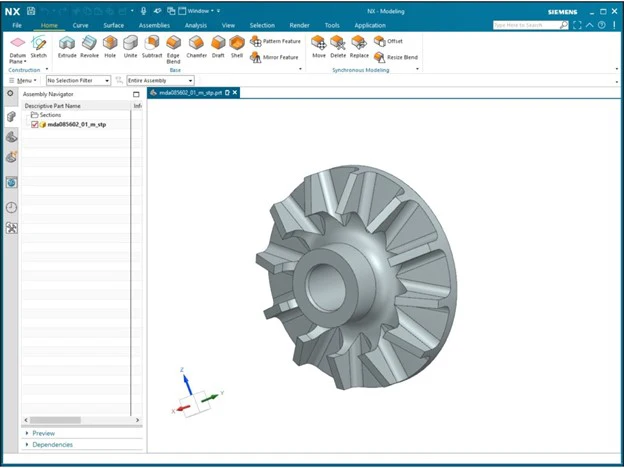

NX Software in 4-Axis Parts Machining

Introduction

As manufacturing advances towards higher precision and efficiency, multi-axis CNC machining technology has become a core method for producing complex parts. Among various multi-axis machining solutions, Siemens NX software stands out significantly in the field of 4-axis machining.

NX Software 4-Axis Machining Overview

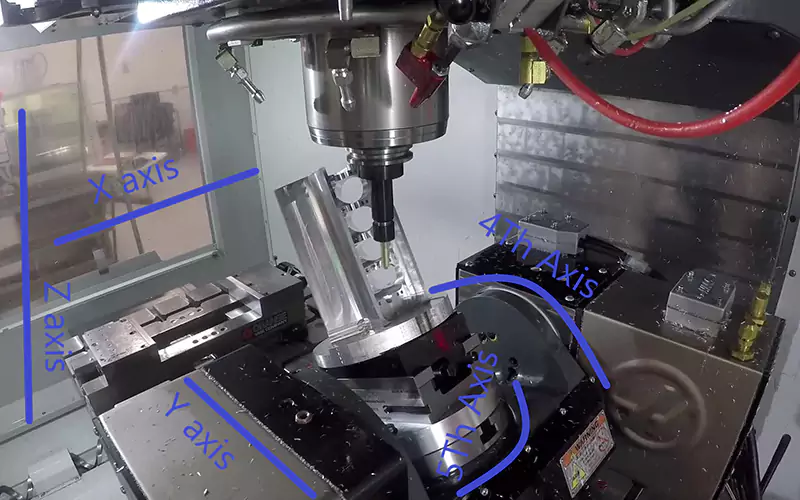

4-axis machining adds a rotational axis (usually A or B axis) to the traditional 3-axis (X, Y, Z) setup. This allows the tool to rotate around a fixed axis, enabling multi-angle machining of complex parts. NX software provides a comprehensive solution for 4-axis machining, including:

- A dedicated 4-axis milling module

- Intelligent tool axis control strategies

- Efficient tool path generation algorithms

- Precise collision detection functions

- An intuitive machining simulation environment

Core Strategies for NX Software 4-Axis Machining

In NX software, model analysis is the foundation of successful 4-axis machining. The focus of analysis includes:

- Geometric characteristics and machining challenges of the part

- Spatial relationship between the rotational axis and the machining surface

- Potential tool interference areas

- Distribution of machining allowances

During the process planning stage, the following factors need to be considered:

- Process division (rough machining, semi-finishing, finishing)

- Clamping schemes and coordinate system settings

- Tool selection (length, diameter, type)

- Preliminary setting of cutting parameters

Tool Axis Control Strategies

Tool axis control is a core technology in 4-axis machining. NX offers various control methods:

- Fixed tool axis strategy: Suitable for simple 4-axis machining, keeping the tool axis at a fixed angle to the rotational axis. Ideal for machining cylindrical and conical surfaces.

- Interpolation tool axis strategy: By defining the start and end directions of the tool axis, NX automatically calculates the tool axis direction at intermediate positions. Suitable for machining smooth transition surfaces.

- Tool axis vertical to component strategy: Maintains the tool perpendicular to the machining surface, particularly suitable for precision machining of complex surfaces.

- Tool axis relative to component strategy: Defines the tool’s forward or side tilt angle relative to the machining surface to optimize cutting conditions.

- Tool axis away from/towards point strategy: Controls the tool to point away from or towards a specific point, suitable for machining radiating features.

Tool Path Optimization Strategies

NX provides the following tool path optimization strategies:

- Regional machining: Divide complex parts into multiple machining regions and adopt the optimal strategy for each region.

- Contour machining: Perform layered cutting in the Z-axis direction, suitable for machining steep areas.

- Helical machining: Generates continuous helical tool paths to improve surface quality and reduce tool lifting.

- Projection machining: Projects 2D tool paths onto 3D surfaces, ideal for complex pattern engraving.

- Adaptive milling: Automatically adjusts cutting parameters based on material removal rates to improve efficiency and protect tools.

Collision Avoidance Strategies

NX provides multi-level collision detection and avoidance mechanisms:

- Tool and workpiece collision detection: Real-time monitoring of interference between the tool and the workpiece.

- Tool holder and fixture collision detection: Ensures the tool holder and chuck do not interfere with fixtures or machine components.

- Automatic avoidance function: Automatically adjusts tool paths when potential collisions are detected.

- Safety plane setting: Defines a safe area for rapid tool movement.

Typical 4-Axis Parts Machining Case Studies

Cylindrical Cam Machining

A cylindrical cam is a typical 4-axis machined part. The machining strategy in NX includes:

- Using the “Curve Driven” or “Streamline Driven” method to generate tool paths.

- Adopting the “Tool Axis Relative to Component” strategy to maintain optimal contact between the tool and the cam surface.

- Setting reasonable guide curves and drive surfaces.

- Using small diameter tools for finishing to ensure contour accuracy.

Turbine Blade Machining

Turbine blades feature complex free-form surfaces. Key points of the NX machining strategy include:

- Using the “Tool Axis Vertical to Component” strategy for precision machining of blade profile surfaces.

- Using “Variable Axis Contour Milling” for root corner cleaning of blades.

- Setting reasonable step distances and cutting directions to ensure surface quality.

- Utilizing the “Side Cutting” function to improve machining efficiency.

Multi-Faceted Parts Machining

For parts requiring machining from multiple angles, NX strategies include:

- Defining multiple machining coordinate systems corresponding to different machining orientations.

- Using a combination of “Planar Milling” and “Contour Milling” strategies.

- Reasonably planning rotational axis movements to minimize idle travel.

- Setting precise rotational axis positioning parameters.

Summary of NX 4-Axis Machining Advantages

- Efficient programming: An intuitive user interface and rich processing templates significantly reduce programming time.

- Intelligent tool axis control: Flexible tool axis definition methods meet various complex machining requirements.

- Precise simulation: Comprehensive machine simulation effectively avoids collision risks in actual machining.

- Optimized algorithms: Advanced tool path algorithms ensure machining efficiency and quality.

- Seamless integration: Deep integration with CAD modules supports seamless transition from design to manufacturing.