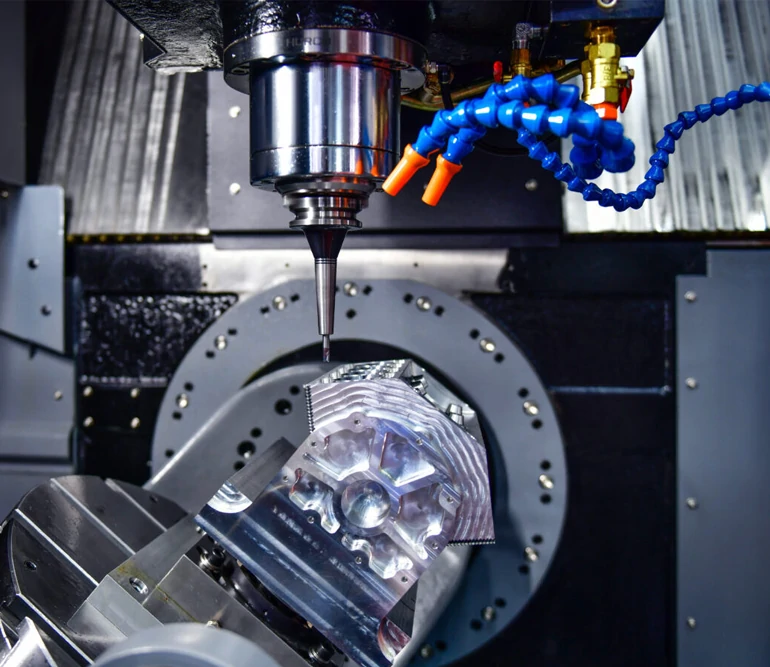

5 Axis Machining: What axes are available?

In modern manufacturing’s fast – evolving landscape, 5-axis machining has become a transformative force, enabling the production of highly complex and precision components. The concept of axes lies at the core of this advanced machining technology. These axes play a crucial role in defining the capabilities and performance of 5-axis machines. In this blog post, we’ll explore the world of 5-axis machining axes in detail, covering their definitions, types, importance, and impact on machining processes.

Understanding Axes in Axis Machining

Before delving into 5-axis machining axes, it’s essential to understand what an axis means in machining. Simply put, in machining, an axis represents a direction of movement or rotation that a machine tool can execute. These axes are usually defined within a three – dimensional coordinate system, with each axis corresponding to a distinct direction of movement or rotation.

Introduction to Axis Machining

Axis machining, also known as CNC (Computer Numerical Control) machining, is a manufacturing process. Manufacturers use computer – controlled machine tools in this process to remove material from a workpiece and create the desired shape or geometry. CNC machines feature multiple axes. These axes can move and rotate in various directions, allowing for the precise and efficient machining of complex parts.

Definition of an Axis

As mentioned earlier, an axis in machining refers to a direction of movement or rotation for a machine tool. In a 5-axis machining system, there are five axes of movement or rotation, typically labeled as X, Y, Z, A, and B. These axes work in harmony. They give the machine the ability to move the cutting tool or workpiece in multiple directions. This enables the machining of complex shapes and geometries that traditional 3-axis machines can’t achieve.

Types of Axes in Machining

X-Axis

The X-axis is one of the three linear axes in a 5-axis machining system. It represents the horizontal movement of the machine tool or workpiece, usually from left to right. In a typical 5-axis machining setup, operators use the X-axis to move the cutting tool or workpiece horizontally across the machine table. This movement allows for machining flat surfaces, slots, and other features that require horizontal movement.

Y-Axis

The Y-axis is another linear axis in a 5-axis machining system. It represents the vertical movement of the machine tool or workpiece, typically from front to back. In a standard 5-axis machining setup, the Y-axis moves the cutting tool or workpiece vertically up and down the machine table. This enables the machining of vertical surfaces, holes, and other features that need vertical movement.

Z-Axis

The Z-axis is the third linear axis in a 5-axis machining system. It represents the depth movement of the machine tool or workpiece, generally from top to bottom. In a common 5-axis machining setup, the Z-axis controls the vertical movement of the cutting tool or workpiece into and out of the workpiece. This facilitates the machining of deep cavities, pockets, and other features that demand depth movement.

A-Axis

The A-axis is one of the two rotary axes in a 5-axis machining system. It represents the rotation of the machine tool or workpiece around the X-axis. In a typical 5-axis machining operation, machinists use the A-axis to tilt the cutting tool or workpiece at an angle. This tilting allows for machining complex shapes and geometries that require angular movement.

B-Axis

The B-axis is the second rotary axis in a 5-axis machining system. It represents the rotation of the machine tool or workpiece around the Y-axis. During a 5-axis machining process, the B-axis rotates the cutting tool or workpiece at an angle. This rotation enables the machining of complex shapes and geometries that involve rotational movement.

C-Axis

The C-axis is the third rotary axis in a 5-axis machining system. It represents the rotation of the machine tool or workpiece around the Z-axis. In 5-axis machining, operators use the C-axis to rotate the cutting tool or workpiece at an angle. This rotation is crucial for machining complex shapes and geometries that require circular or helical movement.

Importance of Axes in Machining

The axes in a 5-axis machining system are vital for determining the machine’s capabilities and performance. Here are some key reasons why axes matter in machining:

- Increased Precision and Accuracy: The ability to move the cutting tool or workpiece in multiple directions allows machinists to machine complex shapes and geometries with greater precision. This is especially important in industries like aerospace, automotive, and medical. These industries demand tight tolerances and high precision.

- Improved Efficiency and Productivity: 5-axis machining can significantly reduce the number of setups and operations needed to machine a part. As a result, it improves efficiency and productivity. The machine can perform multiple operations in a single setup, eliminating the need for manual repositioning.

- Enhanced Flexibility and Versatility: Moving the cutting tool or workpiece in multiple directions enables the machining of a wide range of part geometries and materials. This makes 5-axis machining a highly flexible manufacturing process. It can produce various parts for different industries.

Axis Configuration in CNC Machines

CNC machines can have different axis configurations based on specific machining requirements. Here are some common axis configurations in CNC machines:

- 2-Axis Configuration: A 2-axis CNC machine has two linear axes, usually the X and Y axes. This type of machine is suitable for machining flat surfaces, slots, and other simple geometries.

- 3-Axis Configuration: A 3-axis CNC machine comes with three linear axes, typically the X, Y, and Z axes. It is designed for machining complex geometries that need three-dimensional movement.

- 4-Axis Configuration: A 4-axis CNC machine features three linear axes and one rotary axis, often the X, Y, Z, and A axes. This configuration is ideal for machining parts that require angular movement, such as impellers, turbines, and propellers.

- 5-Axis Configuration: A 5-axis CNC machine has three linear axes and two rotary axes, usually the X, Y, Z, A, and B axes. It is the most advanced and versatile of all CNC machines. It allows for machining complex shapes and geometries with high precision.

How Axes Impact Machining Processes

The axes in a 5-axis machining system significantly influence machining processes in several ways:

- Tool Path Generation: The axes determine the possible tool paths. By moving the cutting tool or workpiece in multiple directions, machinists can generate more complex and efficient tool paths. This results in better machining accuracy and surface finish.

- Cutting Forces and Chip Formation: The movement of the axes also affects cutting forces and chip formation during machining. Controlling the movement of the cutting tool or workpiece can optimize these factors. As a result, it reduces tool wear and improves machining efficiency.

- Machining Time and Cost: The axes can also impact machining time and cost. Reducing the number of setups and operations through 5-axis machining can cut down on machining time and cost. This leads to improved productivity and profitability.

Axis Control Mechanisms

Manufacturers control the axes in a 5-axis machining system using various mechanisms, including servo motors and stepper motors. Here are the key features and benefits of these axis control mechanisms:

- Servo Motors: Servo motors are high-precision electric motors. Machinists use them to control the movement of the axes in a 5-axis machining system. These motors offer precise control over the position, speed, and torque of the axes. This precision results in better machining accuracy and surface finish.

- Stepper Motors: Stepper motors are another type of electric motor for axis control. They are less precise than servo motors but more cost-effective and easier to control. People typically use stepper motors in applications where high precision isn’t necessary.

Axis Calibration Techniques

Axis calibration ensures that the axes in a 5-axis machining system are accurately aligned and functioning well. Here are some common axis calibration techniques in 5-axis machining:

- Laser Interferometry: Laser interferometry is a highly accurate method. Technicians use it to measure the position and movement of the axes. They typically apply this technique in high-precision applications where accurate axis alignment is crucial.

- Ball Bar Testing: Ball bar testing is a simpler and more cost-effective approach. Testers use a ball bar to measure the accuracy and repeatability of the axes. It is suitable for applications where high precision is not a top priority.

- Touch Probe Calibration: Touch probe calibration involves using a touch probe. Operators use it to measure the position and orientation of the workpiece. This technique is useful for applications with complex or irregularly shaped workpieces.

Common Challenges in Axis Machining

Despite its many benefits, 5-axis machining presents several challenges:

- Alignment Issues: One major challenge is ensuring accurate axis alignment. Misaligned axes can lead to poor machining accuracy, surface finish, and tool life.

- Backlash Problems: Backlash can occur when there is play in the axis drive system. It can result in poor machining accuracy, surface finish, and shortened tool life.

- Complex Programming: 5-axis machining requires complex programming skills. The programming process involves generating tool paths, selecting cutting tools, and setting machining parameters. This can be time-consuming and challenging for inexperienced programmers.

Future Trends in Axis Machining

The field of axis machining is constantly evolving. Here are some future trends:

- Increased Automation: Manufacturers will likely use more automation in axis machining. Technologies like robotics, machine vision, and artificial intelligence will play key roles in improving efficiency, productivity, and quality.

- Advanced Materials: The use of advanced materials such as composites, ceramics, and titanium will increase. Axis machining technologies will need development and optimization to handle these materials.

- Virtual Reality and Simulation: Virtual reality and simulation technologies will become more common. Manufacturers will use them to visualize and simulate the machining process, optimizing tool paths and parameters.

Case Studies on Axis Machining

Industry Applications

Axis machining has applications in various industries:

- Aerospace: In aerospace, manufacturers use axis machining to produce complex components like turbine blades, impellers, and engine parts. These parts need high precision and must withstand high temperatures and pressures.

- Automotive: In the automotive industry, axis machining creates components such as engine blocks, cylinder heads, and transmission parts. These components require high precision and the ability to withstand high stresses.

- Medical: In the medical field, axis machining produces components like implants, prosthetics, and surgical instruments. These parts need high precision and biocompatibility.

- Mold Making: In mold making, axis machining produces molds for plastic injection molding, die casting, and other processes. These molds require high precision and must withstand high pressures.

Innovative Solutions

Axis machining is also driving innovative solutions:

- 3D Printing Integration: Combining axis machining with 3D printing creates complex components with better accuracy. This hybrid process merges the benefits of both technologies.

- Micro Machining: Axis machining enables the production of micro components with high precision. These components are used in medical, electronics, and aerospace industries.

- Nanomachining: Axis machining can produce nanoscale components. These find applications in semiconductor, optics, and biotechnology industries.

Best Practices for Axis Machining

To achieve the best results in axis machining, follow these practices:

- Use High-Quality Cutting Tools: High-quality cutting tools are essential for precision. They can withstand high cutting forces and temperatures, improving tool life and surface finish.

- Optimize Tool Paths: Use advanced CAM software to optimize tool paths. This minimizes cutting time and tool wear, improving efficiency.

- Control Machining Parameters: Adjust cutting speed, feed rate, and depth of cut based on the material and cutting tool. This ensures optimal machining results.

- Maintain Machine Tool: Regularly lubricate, clean, and calibrate the machine tool. This maintenance prevents breakdowns and ensures accuracy.

Safety Considerations in Axis Machining

Axis machining involves high-speed cutting tools and heavy machinery. Take these safety precautions:

- Wear Personal Protective Equipment (PPE): Wear safety glasses, gloves, and earplugs to protect against debris, sharp edges, and noise.

- Follow Machine Tool Safety Procedures: Lock out the machine before maintenance. Ensure all guards and safety devices are in place and working.

- Keep the Work Area Clean and Organized: Remove debris and objects from the work area to prevent accidents.

- Train Employees on Safety Procedures: Provide regular safety training to all employees using the machine tool.

Glossary of Terms in Axis Machining

- Axis: A direction of movement or rotation for a machine tool.

- CNC (Computer Numerical Control): A manufacturing process using computer – controlled machine tools.

- Servo Motor: A high-precision electric motor for axis control.

- Stepper Motor: An electric motor for axis control, less precise but cost-effective.

- Tool Path: The path the cutting tool follows during machining.

- Cutting Speed: The speed of the cutting tool through the workpiece.

- Feed Rate: The rate at which the workpiece moves into the cutting tool.

- Depth of Cut: The depth the cutting tool penetrates the workpiece.

- Backlash: Play in the axis drive system affecting machining quality.

- Alignment: Ensuring axes are accurately positioned.

- Calibration: Ensuring axes are accurately calibrated.

Resources for Further Learning

If you want to learn more about axis machining, consider these resources:

- Books: Many books cover CNC programming, machining processes, and machine tool operation.

- Online Courses: Various online courses offer different learning options.

- Manufacturer Websites: Manufacturers provide technical manuals, training videos, and application notes.

- Industry Associations: These associations offer conferences, seminars, and networking opportunities.

Conclusion

In conclusion, the axes in a 5-axis machining system are crucial. Understanding their types, functions, and impact helps in designing, programming, and operating 5-axis machining systems. Whether you’re an experienced machinist or a beginner, mastering axis machining concepts is key to success in modern manufacturing.