6063 Aluminum: How to CNC Machine for Precision Parts

When manufacturing components from 6063 aluminum, understanding its unique properties and machining characteristics is essential for achieving optimal results. This architectural-grade alloy offers exceptional extrudability and surface finish quality, making it ideal for a wide range of CNC applications. Below we’ll explore the complete machining process from material preparation to final finishing.

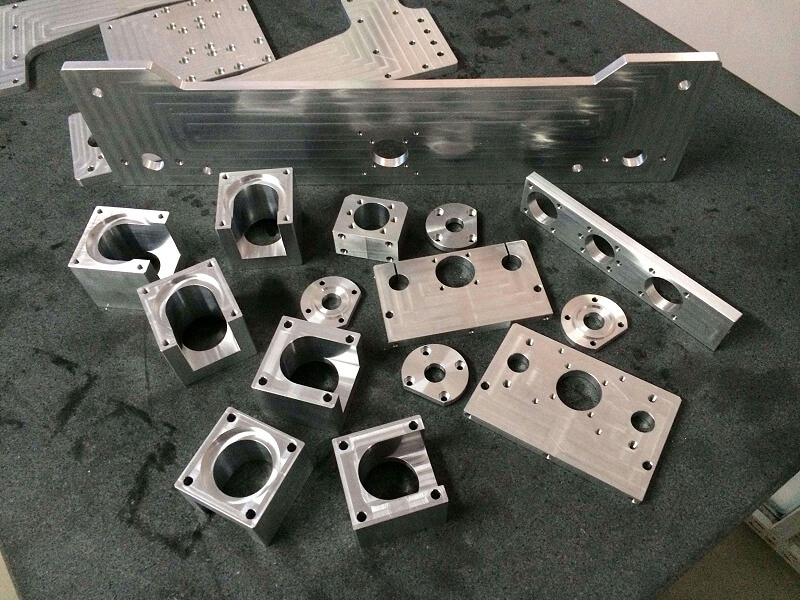

CNC machining centers produce complex aluminum parts

How to cnc machining of aluminum material?

In order to transform aluminum bars into finished parts, manufacturers typically employ several basic CNC operations. Each process requires specific tools and parameters to maximize efficiency while maintaining dimensional accuracy.

1. CNC Milling Operations

Milling is the most versatile machining process for aluminum, capable of producing complex three-dimensional geometries with very tight tolerances. The alloy’s excellent machinability makes it possible to:

- High-speed machining up to 15,000 RPM for small tools

- Aggressive material removal rates with proper toolpaths

- Superior surface finishes compared to other alloys

Pro Tip: Use 3-flute carbide end mills with polished flutes for optimal chip evacuation when milling 6063 aluminum. This prevents material buildup and extends tool life significantly.

2. CNC Turning Processes

For rotational parts, turning provides efficient production of cylindrical components from 6063 aluminum. Key considerations include:

- Sharp positive rake carbide inserts for clean cuts

- Surface speeds between 600-1000 SFM (180-300 m/min)

- High-pressure coolant for chip control

- Light finishing passes for best surface quality

Secondary Machining Operations

After primary machining, several supplementary processes complete the parts to specification. These operations address specific features and functional requirements.

Drilling and Holemaking

Creating precise holes in 6063 aluminum requires:

- Parabolic-flute carbide drills for clean chip removal

- Peck drilling cycles for deep holes

- Proper spot drilling for accurate hole location

- Appropriate feed rates to prevent material galling

Threading Techniques

Both internal and external threads can be effectively produced using:

- Sharp carbide thread mills for precision threads

- Spiral-flute taps for through holes

- Reduced speeds compared to drilling operations

- Specialized cutting fluids for thread forming

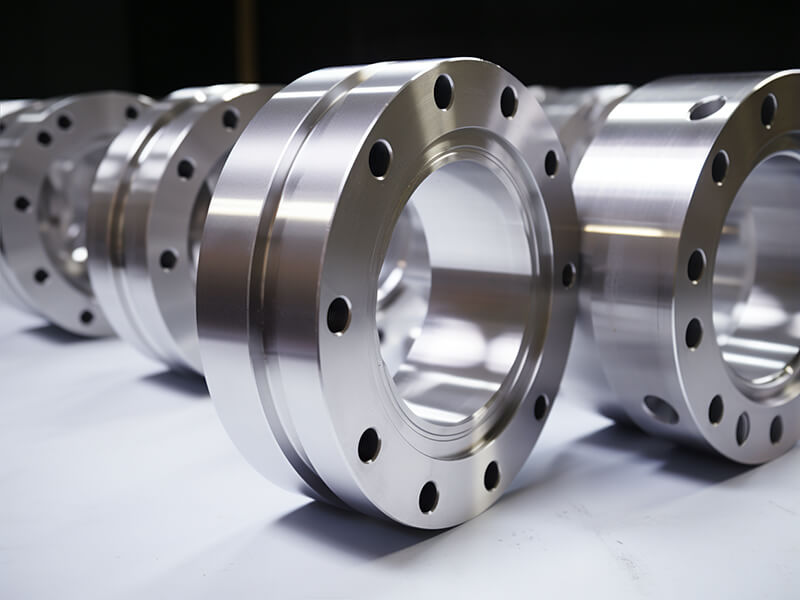

Finished 6063 aluminum parts showing excellent surface quality from proper machining

Optimal Machining Parameters

The table below summarizes recommended cutting parameters for common operations:

| Operation | Tool Material | Speed (SFM) | Feed (IPT) |

|---|---|---|---|

| Rough Milling | Carbide | 800-1200 | 0.005-0.008 |

| Finish Milling | Carbide | 1000-1500 | 0.003-0.005 |

| Turning | Carbide | 600-1000 | 0.004-0.010 |

| Drilling | Carbide | 200-300 | 0.002-0.006 |

Frequently Asked Questions

6063 contains more silicon (0.2-0.6%) and less magnesium (0.45-0.9%) than 6061, making it slightly softer with better extrudability and surface finish. While 6063 machines about 15-20% faster, 6061 offers higher strength for structural applications.

In T6 temper, 6063 aluminum has:

- Tensile strength: 27-30 ksi (186-207 MPa)

- Yield strength: 21-25 ksi (145-172 MPa)

This makes it suitable for architectural and decorative applications.

Yes, using TIG or MIG welding with 4043 or 5356 filler wire. The welded joint will typically have strength between the base materials’ properties when proper techniques are used.

Common tempers include:

- T1: Yield ~13 ksi/90 MPa

- T4: Yield ~16 ksi/110 MPa

- T5: Yield ~22 ksi/152 MPa

- T6: Yield ~25 ksi/172 MPa (most common)