Advantages and Disadvantages of 5-Axis Machined Parts

Introduction

In the world of precision manufacturing, 5-axis machined parts have revolutionized how complex components are produced. Unlike traditional 3-axis machining, 5-axis CNC milling allows for greater flexibility, accuracy, and efficiency in manufacturing intricate geometries. At SCZY LTD, we specialize in high-precision 5-axis machining, delivering superior-quality parts for industries such as aerospace, automotive, medical, and defense.

This article explores the advantages and disadvantages of 5-axis machined parts, helping businesses determine whether this advanced machining method is the right choice for their production needs.

What Are 5-Axis Machined Parts?

5-axis machining refers to a CNC milling process where the cutting tool moves along five different axes (X, Y, Z, and two rotational axes, typically A and B). This enables the machine to approach the workpiece from virtually any angle, allowing for the production of highly complex shapes in a single setup.

Key Features of 5-Axis Machined Parts:

✔ Multi-directional cutting – The tool can move in five axes simultaneously.

✔ Single-setup machining – Reduces repositioning errors and improves accuracy.

✔ High precision – Ideal for tight-tolerance components.

✔ Complex geometries – Capable of producing intricate designs that 3-axis machines cannot.

Advantages of 5-Axis Machined Parts

1. Higher Precision and Accuracy

Since 5-axis machining minimizes the need for multiple setups, it reduces cumulative errors, ensuring better dimensional accuracy and smoother surface finishes. This is crucial for industries like aerospace and medical, where even minor deviations can lead to part failure.

2. Faster Production & Reduced Lead Times

With 5-axis CNC milling, complex parts can be machined in a single operation, eliminating the need for manual repositioning. This significantly reduces cycle times and speeds up production, making it ideal for high-volume manufacturing.

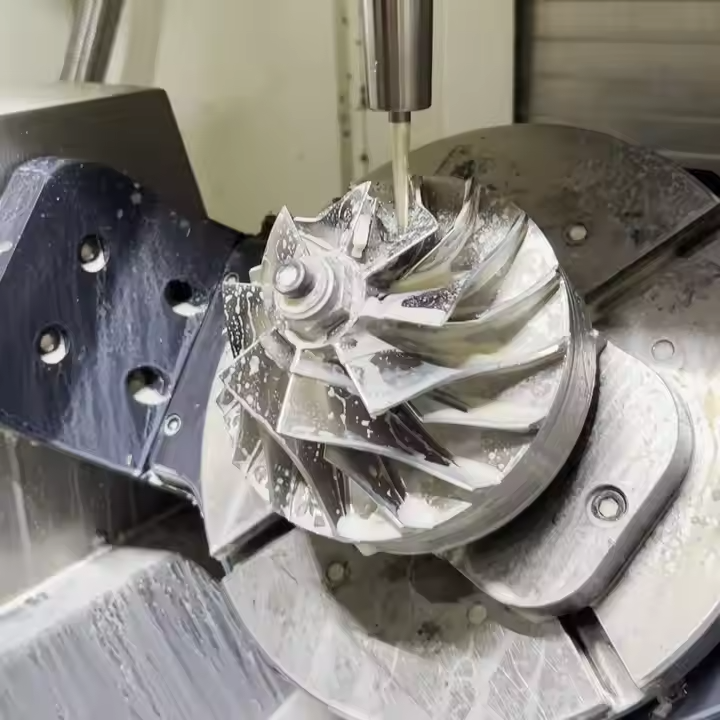

3. Ability to Machine Complex Geometries

Traditional 3-axis machines struggle with deep cavities, undercuts, and organic shapes. 5-axis machining excels in producing:

- Turbine blades

- Aerospace components

- Medical implants

- Automotive prototypes

4. Improved Surface Finish

Since the cutting tool can maintain the optimal angle relative to the workpiece, 5-axis machined parts often require less post-processing, reducing costs and improving aesthetics.

5. Longer Tool Life & Reduced Costs

By optimizing cutting angles and minimizing tool deflection, 5-axis CNC milling extends tool life, lowering operational costs over time.

6. Single-Setup Machining

Unlike 3-axis machines that require multiple setups, 5-axis machining completes parts in one operation, reducing labor costs and potential errors.

Disadvantages of 5-Axis Machined Parts

1. Higher Initial Investment

5-axis CNC machines are significantly more expensive than 3-axis machines, making them a substantial investment for small manufacturers.

2. Complex Programming & Skilled Labor Required

Operating a 5-axis CNC machinerequires highly trained programmers and machinists, increasing labor costs.

3. Potential for Increased Maintenance

Due to their complexity, 5-axis machines may require more frequent calibration and maintenance to ensure precision.

4. Not Always Necessary for Simple Parts

If a part can be efficiently produced on a 3-axis machine, using a 5-axis CNC may be overkill, leading to unnecessary costs.

Industries That Benefit from 5-Axis Machined Parts

1. Aerospace

- Turbine blades

- Engine components

- Structural airframe parts

2. Automotive

- Prototyping

- High-performance engine parts

- Custom automotive components

3. Medical & Dental

- Surgical instruments

- Orthopedic implants

- Dental prosthetics

4. Defense & Military

- Weapon components

- Surveillance equipment

- High-strength structural parts

5. Energy & Oil/Gas

- Turbine components

- Valve bodies

- Pump housings

Why Choose SCZY LTD for 5-Axis Machined Parts?

At SCZY LTD, we combine advanced 5-axis CNC technology with expert engineering to deliver high-precision machined parts for critical industries.

Our Capabilities Include:

✔ High-speed 5-axis milling

✔ Tight tolerances (±0.001″)

✔ Prototyping & mass production

✔ Material expertise (aluminum, titanium, stainless steel, plastics)

Quality Assurance:

- ISO 9001-certified

- Advanced inspection (CMM, optical measurement)

- Strict quality control protocols

Conclusion: Is 5-Axis Machining Right for Your Project?

5-axis machined parts offer unmatched precision, efficiency, and versatility, making them ideal for complex, high-performance applications. However, the higher costs and technical requirements mean they may not be suitable for every project.

If you need high-quality 5-axis machined parts, SCZY LTD provides reliable, cost-effective solutions tailored to your specifications. Contact us today for a quote or consultation!