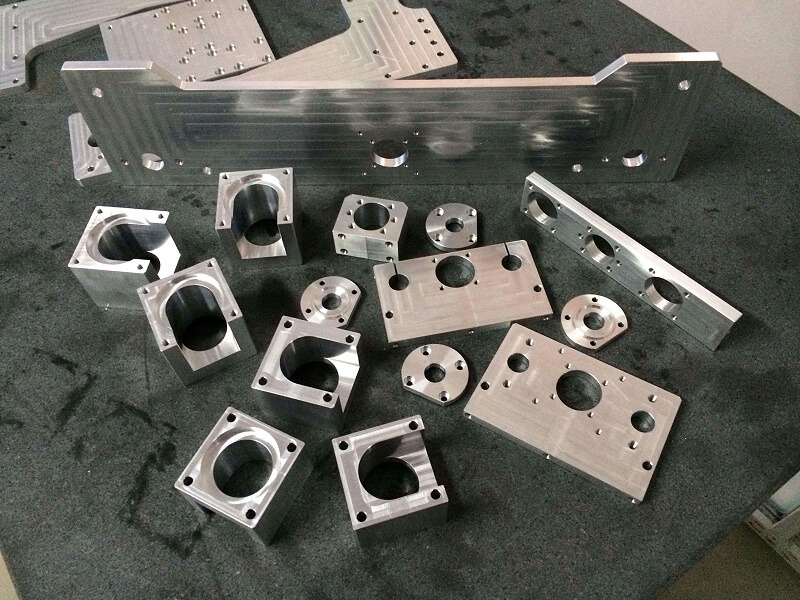

Aluminum CNC Machining: Precision Manufacturing for Modern Industry

1. What is Aluminum CNC Machining?

Aluminum CNC (Computer Numerical Control) machining refers to the automated process of shaping aluminum parts using precision computer-controlled machine tools. This subtractive manufacturing technique removes material from aluminum workpieces to create complex geometries with tight tolerances, typically within ±0.005 inches (±0.13 mm) or better.

Modern CNC machining centers can achieve surface finishes as smooth as 8-16 µin (0.2-0.4 µm) on aluminum components, making them ideal for both functional and aesthetic applications.

2. A Brief History of Aluminum CNC Machining

The evolution of aluminum machining parallels key technological advancements:

- 1940s-50s: Early numerical control (NC) machines developed for aerospace aluminum components

- 1960s: Introduction of computer-controlled machining for aluminum aircraft parts

- 1980s: Widespread adoption of CNC technology in aluminum automotive manufacturing

- 2000s: High-speed machining (HSM) techniques optimized for aluminum alloys

- Present: 5-axis CNC systems enabling complex aluminum geometries with single setups

3. How Does Aluminum CNC Machining Work?

The aluminum CNC process involves several key stages:

- CAD Design: Creation of 3D models using computer-aided design software

- CAM Programming: Conversion of designs into machine-readable G-code

- Workpiece Setup: Secure clamping of aluminum stock in the machine

- Tool Selection: Choosing appropriate end mills, drills, and inserts

- Machining Operations: Precise material removal through milling, turning, or drilling

- Quality Inspection: Verification of dimensional accuracy and surface finish

3.1 Aluminum CNC Milling Process

CNC milling of aluminum typically uses:

- Spindle speeds: 8,000-20,000 RPM

- Feed rates: 100-500 inches per minute (IPM)

- Depth of cut: 0.5-1.5 × tool diameter

4. Differences Between Aluminum CNC Machining Processes

| Process | Advantages | Limitations | Typical Tolerances |

|---|---|---|---|

| 3-Axis Milling | Cost-effective, simple setup | Limited complex geometries | ±0.005″ (±0.13mm) |

| 5-Axis Milling | Complex parts in single setup | Higher machine costs | ±0.003″ (±0.08mm) |

| CNC Turning | Excellent for rotational parts | Limited to axisymmetric shapes | ±0.002″ (±0.05mm) |

| Swiss Machining | Precision for small diameter parts | Specialized equipment | ±0.0005″ (±0.013mm) |

5. Aluminum Post-Processing Techniques

Common finishing methods for CNC machined aluminum:

- Bead Blasting: Creates uniform matte surface (Ra 50-100 µin)

- Anodizing: Increases corrosion resistance (Type II: 0.0002-0.001″ thickness)

- Powder Coating: Durable colored finish (2-4 mil thickness)

- Chemical Film: Conductive coating for electronics (0.00002-0.0002″)

- Polishing: Mirror finishes (Ra < 8 µin achievable)

6. Tools and Equipment for Aluminum CNC Machining

Essential tooling for optimal aluminum machining:

- Cutting Tools: 2-3 flute carbide end mills, PCD tools for high volume

- Workholding: Vacuum chucks, vises with aluminum jaws

- Coolant Systems: Mist or flood coolant with 5-10% concentration

- Tool Holders: HSK or BT tapers for high-speed stability

- Measurement: CMMs, optical comparators, surface testers

7. Best Aluminum CNC Machining Machines

Top-performing CNC systems for aluminum:

- Haas VF-4SS: High-speed 3-axis (15,000 RPM, 1,400 IPM)

- DMG MORI CMX 50U: 5-axis universal milling (18,000 RPM)

- Mazak VARIAXIS i-700: 5-axis simultaneous machining

- Okuma GENOS M560-V: Vertical machining center (20,000 RPM)

- Hurco VMX60SR: High-performance 3+2 axis machining

8. Main Parameters of Aluminum CNC Machining

Critical machining parameters for aluminum:

- Cutting Speed (Vc): 500-3,000 SFM (varies by alloy)

- Feed per Tooth (Fz): 0.003-0.020 inches

- Axial Depth of Cut (Ap): 0.5-2 × tool diameter

- Radial Depth of Cut (Ae): 10-50% of tool diameter

- Chip Load: 0.001-0.010 inches per tooth

9. Most Suitable Aluminum Alloys for CNC Machining

Machinability ratings of common aluminum alloys (1=best, 5=worst):

- 6061-T6: Rating 1 – Excellent machinability, general purpose

- 7075-T6: Rating 2 – High strength aerospace alloy

- 2024-T3: Rating 2 – Aircraft structural components

- 5052-H32: Rating 1 – Excellent for marine applications

- 6082-T6: Rating 1 – European equivalent to 6061

10. Industrial Applications of CNC Machined Aluminum

Major industries utilizing aluminum CNC components:

- Aerospace: Aircraft structural parts, brackets (30% weight savings vs steel)

- Automotive: Engine blocks, suspension components (15-20% better fuel efficiency)

- Electronics: Heat sinks, enclosures (thermal conductivity 205 W/mK)

- Medical: Surgical instruments, imaging equipment components

- Robotics: Lightweight arms, joints (1/3 density of steel)

11. Advantages and Disadvantages of Aluminum CNC Machining

Advantages:

- 60% faster machining than steel (higher material removal rates)

- 5-10x longer tool life compared to machining stainless steels

- Excellent strength-to-weight ratio (tensile strength 40-80 ksi)

- Superior thermal conductivity (2-5x better than titanium)

- 100% recyclable with 95% energy savings vs primary production

Disadvantages:

- Lower hardness (HB 60-120) compared to steel (HB 120-300)

- Potential for built-up edge (BUE) at improper cutting parameters

- Thermal expansion coefficient 23 µm/m°C (requires compensation)

- Some alloys prone to stress corrosion cracking

12. Software for CNC Machining of Aluminum

Essential software tools:

- CAD: SolidWorks, Autodesk Inventor, CATIA

- CAM: Mastercam, Fusion 360, PowerMill

- Simulation: Vericut, NCSIMUL

- Toolpath Optimization: VoluMill, HSMAdvisor

13. Cost Factors in Aluminum CNC Machining

Typical pricing considerations:

- Machine time: $75-$150/hour for 3-axis, $120-$250/hour for 5-axis

- Material costs: $2-$10/lb for common alloys

- Setup charges: $50-$300 per part configuration

- Tolerances: ±0.005″ standard, ±0.001″ adds 20-50% cost

- Surface finish: 125 µin standard, 32 µin adds 15-30%

14. Key Considerations When Machining Aluminum

Critical factors for successful aluminum machining:

- Proper chip evacuation (prevents recutting)

- Optimized coolant application (reduces built-up edge)

- Appropriate tool coatings (TiB2, ZrN recommended)

- Rigid setups (minimize vibration)

- Sharp tools (HSS or carbide with positive rake)

15. Design Tips for Aluminum CNC Machining

Optimization strategies:

- Maintain wall thickness > 0.020″ (0.5mm) for structural integrity

- Standard hole sizes reduce costs (drills vs end mills)

- Internal radii should be ≥ 1/3 × cavity depth

- Textured surfaces hide tool marks (reduces finishing needs)

- Design for single setup machining when possible

16. Safety Tips for Aluminum CNC Machining

Essential safety practices:

- Wear ANSI Z87.1 safety glasses (flying chips hazard)

- Use proper hearing protection (85+ dB noise levels)

- Implement dust collection (aluminum powder is explosive)

- Follow lockout/tagout procedures during maintenance

- Properly ground machines (prevents static buildup)

17. Environmental Impact of Aluminum CNC Machining

Sustainability considerations:

- Recycling aluminum saves 95% energy vs primary production

- Proper coolant management reduces water contamination

- Chip recycling programs recover 98% of material

- Energy-efficient CNC machines reduce carbon footprint

- Dry machining possible for some operations

18. Common Problems in Aluminum CNC Machining

| Problem | Causes | Solutions |

|---|---|---|

| Built-up edge | Low speeds, improper tool geometry | Increase SFM, use sharper tools |

| Poor surface finish | Vibration, dull tools | Reduce stickout, increase RPM |

| Dimensional inaccuracy | Thermal expansion, tool deflection | Compensate in program, lighter cuts |

| Chip welding | Insufficient coolant | Increase coolant flow, use mist |

19. Aluminum vs Other Metals in CNC Machining

Comparative machining characteristics:

- Machining Speed: Aluminum 3-5x faster than steel

- Tool Wear: 10% of that when machining titanium

- Power Consumption: 40% less than stainless steel

- Surface Finish: Achieves 2x better Ra than cast iron

- Chip Formation: Continuous chips vs segmented in magnesium

20. Alternative Technologies to Aluminum CNC Machining

Competing manufacturing methods:

- Die Casting: Better for >10,000 parts, limited geometries

- 3D Printing: SLM/DMLS for complex internal features

- Extrusion: Cost-effective for constant cross-sections

- Sheet Metal: Faster for thin-walled enclosures

- Investment Casting: Better for certain complex shapes

21. Choosing an Aluminum CNC Machining Service

Selection criteria:

- Verify machine capabilities (3/4/5-axis, size capacity)

- Check material certifications (AMS, ASTM, MIL specs)

- Review quality systems (ISO 9001, AS9100, etc.)

- Evaluate metrology equipment (CMM capability)

- Assess secondary service offerings (anodizing, etc.)

22. Conclusion

Aluminum CNC machining remains the preferred manufacturing method for high-precision, lightweight components across aerospace, automotive, and electronics industries. With proper tool selection, machining parameters, and design considerations, manufacturers can achieve exceptional results at competitive costs. The combination of aluminum’s excellent machinability and modern CNC technology enables production of complex parts with tolerances within 0.001 inches, surface finishes under 16 µin Ra, and production rates unmatched by most other metalworking processes.

As technology advances, aluminum CNC machining continues to evolve with innovations in high-speed machining, micro-machining, and hybrid manufacturing techniques that combine additive and subtractive processes. For most applications requiring precision metal components, CNC machined aluminum offers the optimal balance of performance, cost, and manufacturing efficiency.