Can ChatGPT Create Usable CNC G-code Programs?

The manufacturing industry is actively debating whether AI tools like ChatGPT can reliably generate production-ready CNC G-code. While the technology demonstrates surprising capability with basic programming tasks, professional machinists report both exciting possibilities and critical limitations when using AI for precision machining operations.

How Accurate Is AI-Generated G-code for CNC Milling Operations?

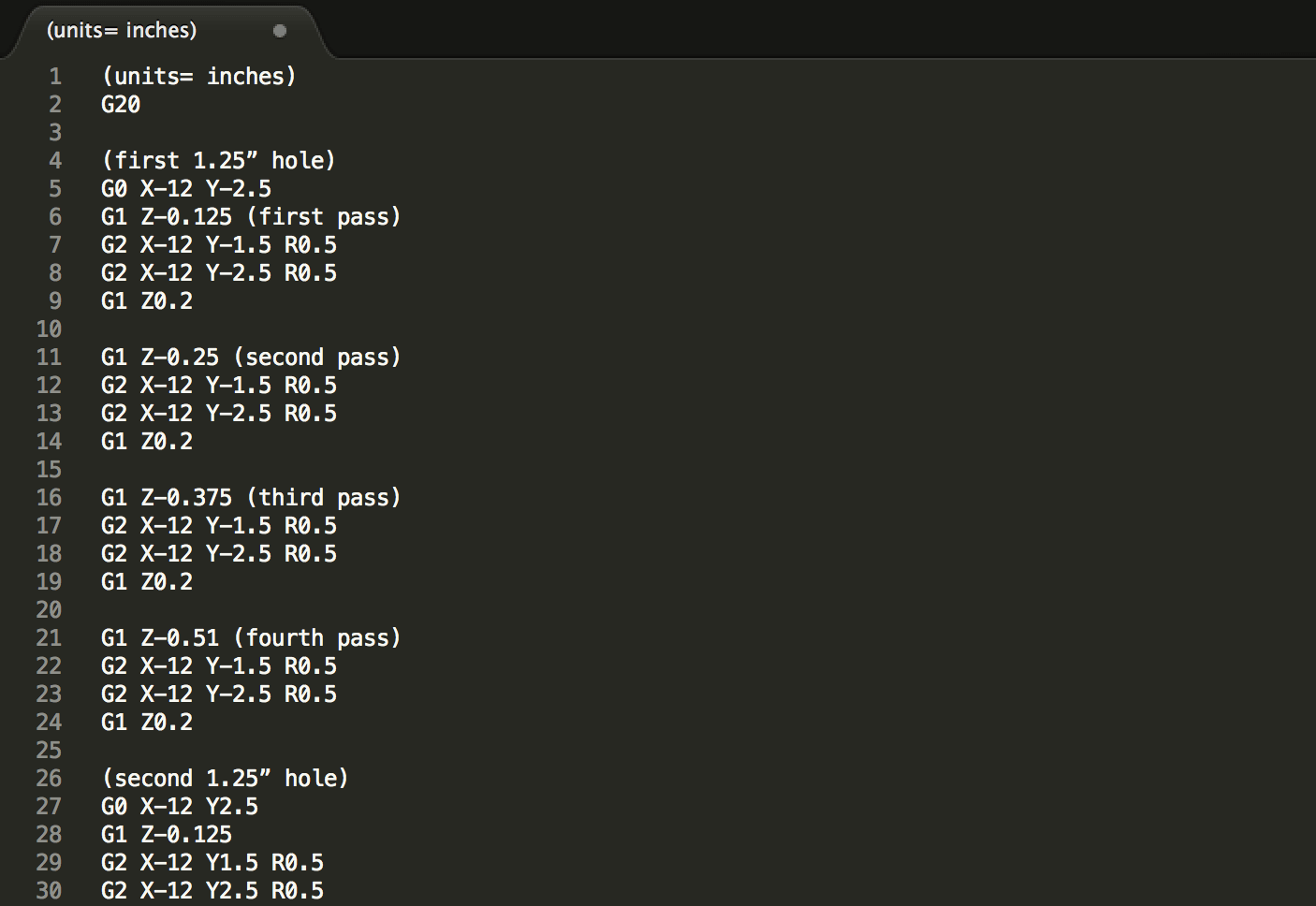

Multiple machine shops have tested ChatGPT’s ability to create functional CNC programs, with varying results. For straightforward tasks like drilling patterns or facing operations, the AI often produces valid G-code that runs successfully on CNC mills. However, when programmers request complex 3D contours or optimized toolpaths, the generated code frequently contains errors in coordinate calculations or inefficient tool movements. Notably, while the AI understands G-code syntax, it lacks practical knowledge of optimal cutting parameters for different materials and tooling.

Can ChatGPT Replace Traditional CAM Software for CNC Programming?

Despite its capabilities, ChatGPT falls short of replacing dedicated CAM systems for several reasons. First, the AI cannot account for specific machine tool configurations or controller compatibility issues. Second, it lacks visual verification tools to prevent tool collisions. Moreover, while it can explain G-code commands, it doesn’t intuitively understand machining best practices like proper chip load management or adaptive toolpaths. Most importantly, without physical machine awareness, AI-generated programs may contain dangerous errors that could damage expensive equipment.

Best Practices for Using AI-Generated G-code in CNC Workshops

Forward-thinking manufacturers are finding safe ways to integrate ChatGPT into their CNC programming workflows. Many use the AI to generate code templates for common operations, which experienced programmers then refine. Others employ it as an educational tool to explain complex G-code commands or troubleshoot existing programs. When testing AI-generated code, experts recommend three essential steps: First, always simulate in CAM software. Second, perform dry runs with reduced feed rates. Third, manually verify all tool offsets and work coordinates before production.

Top 5 Limitations of Using ChatGPT for CNC Lathe Programming

Professional machinists identify several critical constraints when using AI for turning operations: 1) Inability to properly calculate thread cutting cycles 2) Lack of understanding about optimal insert selection 3) Frequent errors in taper and radius calculations 4) No accounting for machine-specific canned cycles 5) Dangerous feed rate suggestions for hard materials. These limitations mean human verification remains essential, especially for precision turning applications.

Conclusion: AI as a Valuable CNC Programming Assistant

While ChatGPT cannot yet replace skilled CNC programmers, it serves as a powerful productivity tool. The technology excels at generating basic G-code structures and explaining complex commands, potentially reducing programming time by 20-30% for routine operations. As AI continues to evolve, the most effective approach will combine its speed and knowledge base with human machining expertise – creating a collaborative future for CNC programming.