What is CNC Mill Parts, Definition, Services, Benefits

Definition of CNC Mill Parts

Essential components that make up a CNC (Computer Numerical Control) milling machine are known as CNC mill parts. These parts work together to enable precise and automated milling operations. Key components include the spindle, milling head, table, control panel, drive system, and coolant system.

The spindle, which is the central part of the CNC mill, holds and rotates the cutting tool at high speeds. This component is crucial for the accuracy and efficiency of the milling process. Similarly, the milling head houses the spindle and allows for its movement and positioning. It can be adjusted to different angles and heights to accommodate various milling tasks.

The table, where the workpiece is mounted, is designed to move in multiple axes (typically X, Y, and Z) to position the workpiece relative to the cutting tool. Likewise, the control panel serves as the interface where operators input commands and control the machine’s movements. Modern CNC mills often feature advanced software and user-friendly interfaces for programming and monitoring the milling process.

The drive system, comprising motors and drive mechanisms, powers the movement of the table and the spindle. It ensures precise and coordinated motion during milling operations. In addition, the coolant system delivers a steady flow of coolant to the cutting area to prevent overheating and maintain tool life, helping to dissipate heat and flush away chips.

Services Related to CNC Mill Parts

Integral to a wide range of services in the manufacturing industry, CNC mill parts are used in precision machining, custom machining, prototyping, production machining, and repair and maintenance.

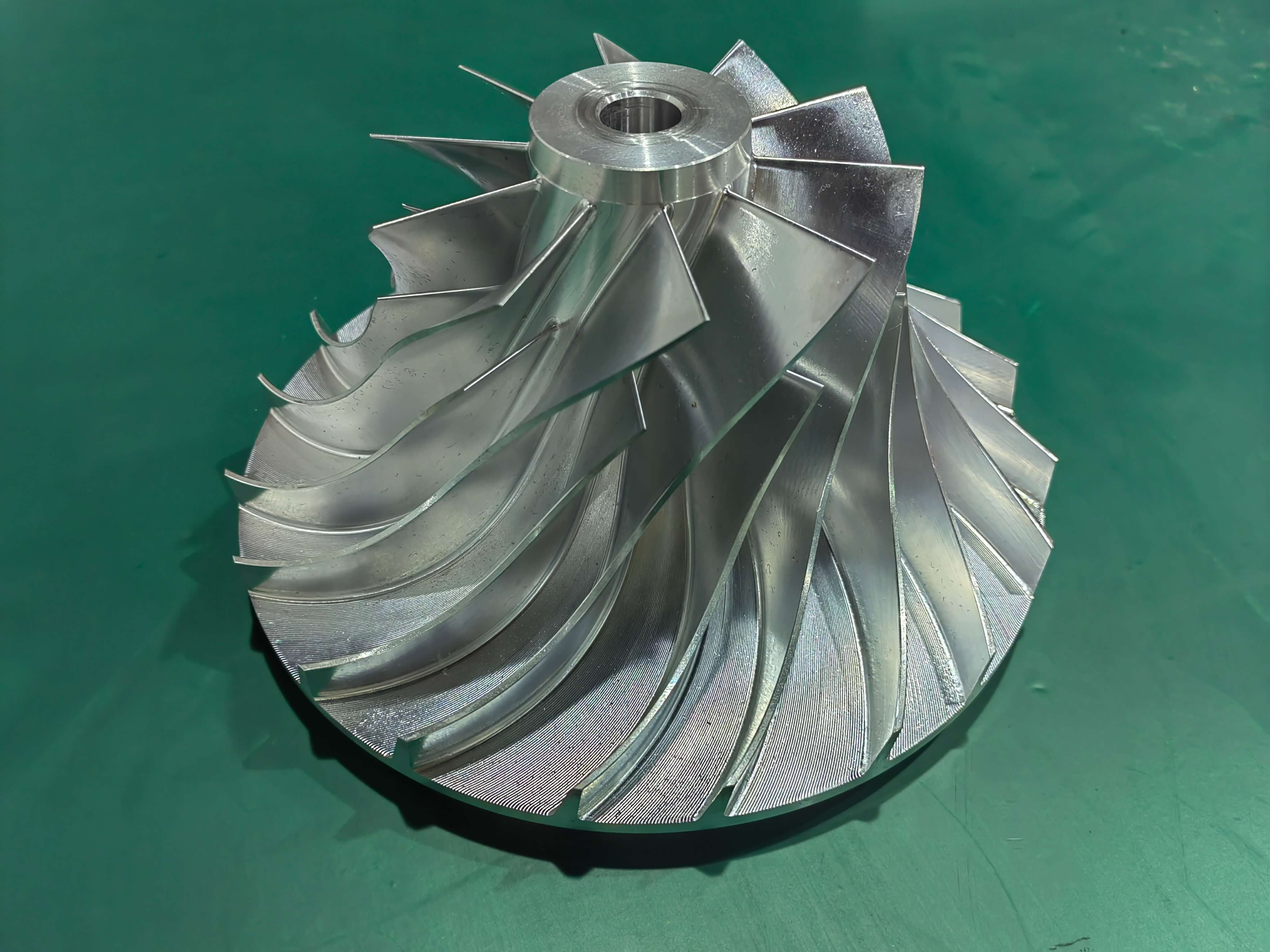

Precision machining services utilize CNC mills to create highly precise components for various industries such as automotive, aerospace, and medical. The accuracy of these parts ensures that the final products meet tight tolerances. Custom machining allows CNC mills to be programmed to produce custom parts based on specific customer requirements. This flexibility enables the creation of unique components that are not readily available off-the-shelf.

In product development, CNC mills are employed to create prototypes quickly and accurately, enabling rapid iteration and testing of new designs. For high-volume production runs, CNC mills equipped with reliable parts can operate continuously, ensuring consistent quality and efficiency. Similarly, these parts are essential for the repair and maintenance of milling machines. Regular maintenance and timely replacement of worn parts help extend the machine’s lifespan and maintain its performance.

Benefits of CNC Mill Parts

The use of CNC mill parts offers numerous advantages in manufacturing and machining processes. These benefits include high precision and accuracy, increased productivity, the ability to handle complex designs, improved quality, reduced labor costs, and enhanced safety.

Designed to operate with high precision, these parts result in accurate and consistent machining outcomes. This precision is crucial for producing parts that meet tight tolerances and fit perfectly in their intended applications. Automation and precise control enable faster machining processes. The ability to run multiple operations without manual intervention increases overall productivity and reduces lead times.

CNC mills can handle complex geometries and intricate designs that would be difficult or impossible to achieve with manual machining. This capability opens up possibilities for creating innovative and advanced products. The consistency and repeatability of these parts contribute to higher quality end products. Each part produced is identical to the others, ensuring uniformity and reliability.

The automation provided by these parts reduces the need for manual labor, lowering labor costs and minimizing the risk of human error. Similarly, CNC mills are designed to operate with minimal human intervention, reducing the risk of accidents and injuries in the workplace. The enclosed nature of many CNC machines also helps protect operators from flying debris and other hazards.

Summary

To summarize, CNC mill parts are indispensable components that drive the precision and efficiency of CNC milling machines. They are fundamental to a variety of machining services, from precision and custom machining to prototyping and large-scale production. The benefits they offer, such as high precision, increased productivity, and enhanced safety, make them a cornerstone of modern manufacturing. Whether you are looking to create intricate designs, reduce labor costs, or ensure consistent quality, these parts are a vital part of the solution.