CNC Precision Machined Parts: The Mystery of High-Precision Manufacturing

What is CNC Precision Machining?

As stated by industry experts, CNC precision machining represents a revolutionary approach to manufacturing. This technology leverages computer-controlled machinery to produce components with exceptional accuracy and consistency.

In the words of manufacturing professionals, CNC machining has transformed production by eliminating human error and enhancing repeatability. Parts are crafted according to precise specifications, often achieving tolerances as tight as +/- 0.0001 inches.

CNC Precision Machined Parts

According to leading manufacturers, CNC precision machined parts are utilized across numerous sectors. These include aerospace, medical, automotive, and defense industries, where precision and reliability are paramount.

As noted by technical specialists, these parts range from simple shapes to highly complex geometries. Each is produced with exacting standards to ensure functionality, safety, and longevity in their intended applications.

Why CNC Precision Machined Parts?

As highlighted by industry analysts, CNC precision machined parts offer several key advantages:

- Accuracy: As mentioned in manufacturing reports, CNC machining ensures parts adhere to precise guidelines, meeting exact specifications.

- Reproducibility: According to production studies, CNC processes yield consistent results across large manufacturing runs.

- Efficiency: As stated by efficiency experts, CNC machining minimizes material waste and maximizes productive manufacturing time.

- Cost-Effectiveness: According to cost analysis reports, despite initial investment, CNC machining reduces long-term expenses by minimizing labor, waste, and errors.

- Design Flexibility: As noted by design professionals, CNC technology allows for the creation of complex and customized parts tailored to specific project requirements.

Main Processes Involved in CNC Machining

According to detailed industry documentation, the CNC machining process comprises several essential steps:

- Design and CAD Modeling: As explained by engineering specialists, engineers create detailed 2D or 3D models using CAD software. These models include critical details such as dimensions and tolerances.

- CNC and CAM Programming: As described by programming experts, CAM software converts CAD models into G-code, generating machine-readable instructions that guide the CNC machine’s movements and operations.

- Setup CNC Machine: According to setup technicians, this involves selecting appropriate cutting tools, securing the workpiece, and ensuring proper calibration and alignment for optimal precision.

- Machining Operation: As outlined in operational guides, the CNC machine follows programmed instructions to precisely remove material from the workpiece, shaping it into the desired form.

- Post-Production Finishing: According to finishing specialists, processes such as grinding, deburring, sandblasting, electroplating, and polishing may be applied to achieve the required precision and surface quality.

Methods of CNC Precision Machining Parts

As reported by manufacturing methodologists, CNC precision machining employs various techniques:

- CNC Turning: As described by turning specialists, this method involves rotating a workpiece on a lathe while a cutting tool shapes it into cylindrical or conical forms. It is ideal for producing large quantities of identical parts with excellent dimensional accuracy.

- 3-Axis CNC Machining: According to machining experts, this method utilizes three linear axes (X, Y, and Z) to create parts with moderate complexity. It is suitable for producing simple to moderately complex shapes like housings, plates, and molds.

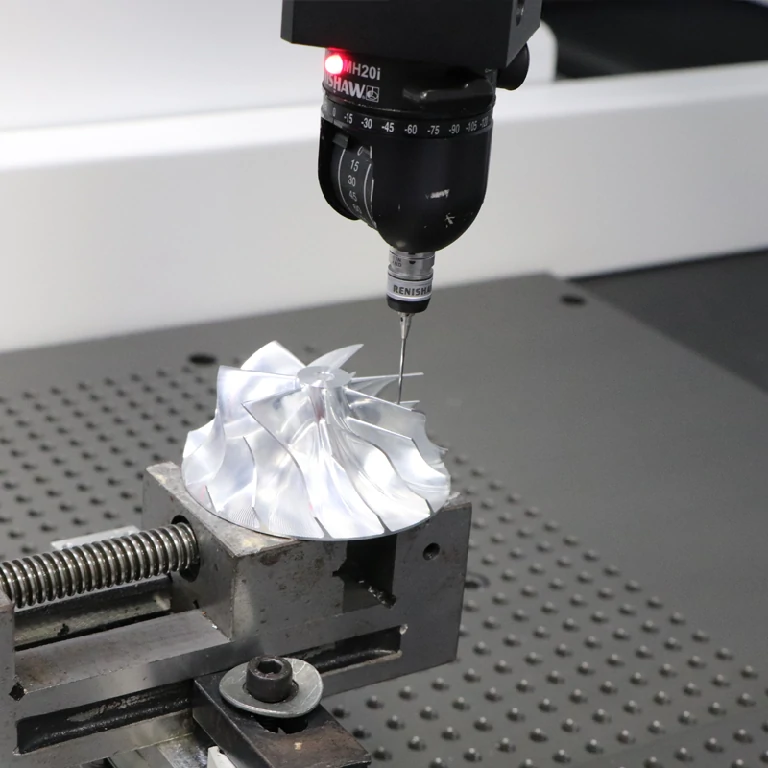

- 5-Axis CNC Machining: As noted by advanced machining specialists, this method offers unparalleled versatility by enabling movement along three linear axes and two rotational axes. It allows the production of highly complex components with intricate geometries and tight tolerances.

- CNC Boring: According to boring technicians, this precision process enlarges and refines pre-drilled holes. It ensures precise diameters and superior surface finishes. It is crucial for applications requiring accurate hole dimensions and surface quality.

Applications of CNC Precision Machining

As highlighted by application engineers, CNC precision machining is utilized across numerous industries:

- Aerospace: As stated by aerospace specialists, this industry relies on CNC machining for critical components such as turbine blades, landing gear parts, and structural components. These parts must withstand extreme conditions while maintaining exacting tolerances.

- Medical Devices: According to medical device experts, CNC machining creates life-saving devices and instruments. These include surgical tools, implant components, and diagnostic equipment parts with exceptional accuracy and biocompatibility.

- Automotive: As noted by automotive engineers, CNC machining produces high-performance engine components, chassis parts, and gears. This ensures vehicle reliability, safety, and performance in a competitive market.

- Defense: According to defense industry analysts, CNC machining produces components for weapons systems, military vehicles, and aerospace applications. These components require high precision and unwavering reliability.

Importance of CNC Precision Machined Parts Manufacturers

As emphasized by industry consultants, CNC precision machined parts manufacturers play a crucial role in various sectors. They possess the expertise, technology, and equipment necessary to produce components that meet exacting standards. By partnering with reliable manufacturers, businesses can ensure the quality, precision, and timely delivery of parts essential for their operations. As stated by supply chain specialists, these manufacturers are vital for driving innovation and advancement in industries where precision and reliability are non-negotiable.

Final Thoughts

As concluded by manufacturing futurists, CNC precision machined parts are central to modern manufacturing. They enable the production of components with exceptional accuracy and reliability. As industries continue to evolve and demand higher precision, the role of CNC precision machining will only become more significant. By understanding the processes, methods, and applications of CNC precision manufacturing, businesses can leverage this technology to achieve their goals and drive progress across various fields. As noted by industry visionaries, embracing CNC precision machining is not just a technological choice—it’s a commitment to quality, innovation, and excellence that opens doors to new opportunities and drives advancement worldwide.