Precision investment casting services

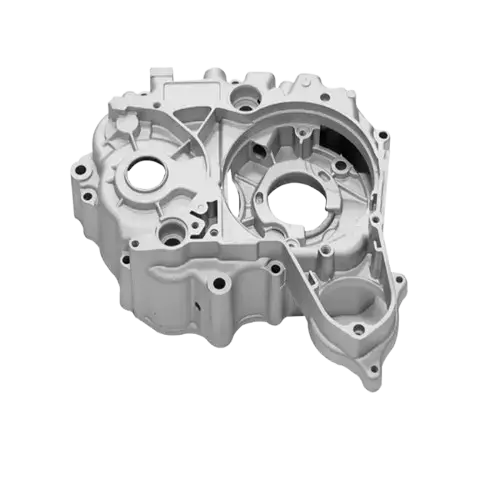

We use the most advanced precision casting technology to create high quality casting products for our customers.

Clients we serve

Asia's top precision investment casting

SCZY LTD is Asia’s leading precision casting service provider. Our team of engineers, technicians and quality control specialists work together to ensure that your products are delivered perfectly once and for all. Our precision investment casting services are also complemented by our many other manufacturing solutions, including CNC machining and 3D printing, to provide you with a full range of manufacturing solutions for your products.

We can help you cast parts in a variety of metals, including stainless steel, brass, aluminum, carbon steel, brass, bronze, tool steel and cobalt.

What is investment casting?

Precision investment casting, also known as investment casting, is a lost wax casting process used to manufacture ferrous and non-ferrous metal parts. By “lost wax casting” we mean casting metal parts in wax molds.

The investment casting process begins with the design and manufacture of a wax mold, which is used to create a wax mold with the same geometry as the desired finished part. Depending on the complexity of the design, you may need to make one or as many as twenty wax molds. The goal is for the molds to form the geometry of the desired finished casting when assembled.

Next, the assembled wax molds are immersed in a ceramic slurry until a ceramic mold is formed. The ceramic molds are preheated, filled with molten metal, allowed to solidify, and then removed to form the desired metal casting.

Why precision investment casting?

Precision casting offers a number of advantages over other manufacturing processes. For example, the process reduces manufacturing costs by eliminating material waste common in subtractive manufacturing techniques such as CNC machining. In addition, it reduces the longer production times common in metal fabrication processes such as welding.

In addition, investment casting allows for the manufacture of complex parts that may be more difficult to manufacture with CNC machines. So let’s say you need to make complex internal passages in metal parts, curved blades for an impeller, or cooling waterways in complex equipment, and need a high surface finish. In this case, you must consider using precision investment casting.

Precision casting can also produce complex shapes, just like the precision investment casting process. However, because the forging process requires specially designed molds, the associated tooling costs are higher than with precision casting. Additionally, precision casting offers greater design freedom and is capable of producing larger, more complex geometries than other manufacturing techniques.

Advantages of investment casting

highly accurate

customization

Smooth surface

Design Freedom

High-quality materials

Wide range of sizes

investment casting solutions

Precision Casting

- Advanced technology: ensures tight tolerances to +/- 0.01 mm.

- Material expertise: proficient in stainless steel and carbon steel.

- Flexible production: Suitable for both high and low volume production needs.

Customized precision Solutions

- Total Quality Control: Strict processes are in place at every manufacturing stage.

- Quick turnaround: optimize production workflow for fast delivery.

- Support for complex designs: Ability to handle complex designs and complex geometries.