Introduction to CNC Machining

CNC (Computer Numerical Control) machining is a transformative manufacturing technology that converts digital designs into physical parts through automated, precision-controlled processes. This advanced manufacturing method enables production of components with tolerances as tight as ±0.001 inches (0.025mm), making it indispensable across industries from aerospace to medical devices.

Working Principle of CNC Machining

1. Computer system

The control center that interprets CAD designs into machine instructions (G-code). Modern systems feature 32-bit processors capable of executing complex tool paths with micron-level precision.

2. Machine tools

Precision-engineered equipment including servo motors that position tools with 0.0001-inch resolution and spindle assemblies rotating up to 50,000 RPM for high-speed machining.

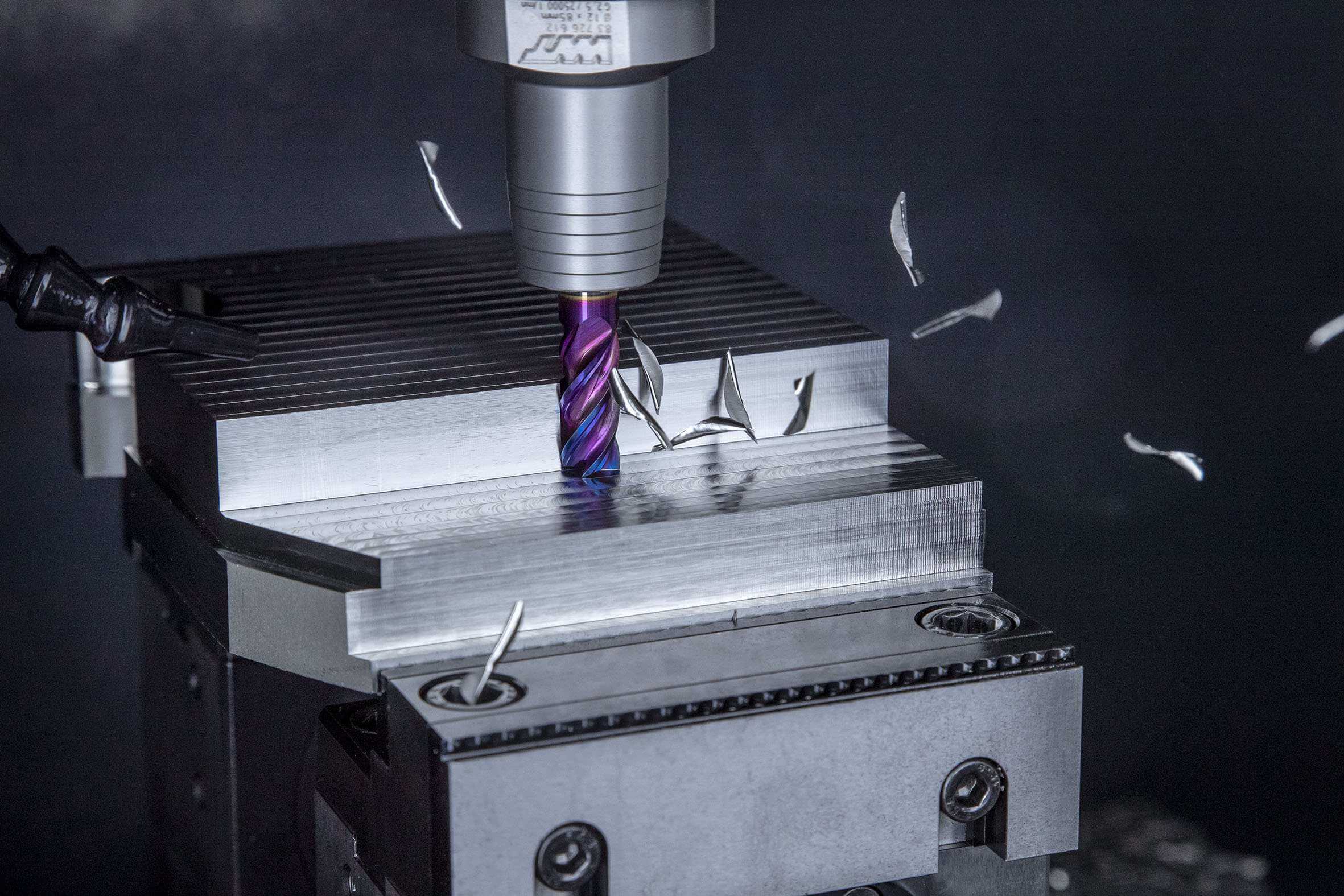

3. Cutting tools

Specialized implements like carbide end mills with advanced coatings (TiAlN, diamond-like carbon) that maintain sharpness when cutting hardened steels up to HRC 65.

Types of CNC Machine Tools

- CNC milling machine: 3-5 axis systems capable of complex contouring (e.g., machining turbine blades from Inconel 718)

- CNC Lathe: Swiss-type machines producing precision shafts with ±0.0005″ tolerances

- CNC Router: Gantry-style cutters handling 4’×8′ sheets of aluminum or composites

- CNC plasma cutting machine: Cutting 1″ steel plate at 200 IPM with ±0.020″ accuracy

- CNC grinding machine: Achieving surface finishes to 0.1μm Ra on hardened tool steels

Main Advantages of CNC Machining

- Unrivaled precision and accuracy: Holding ±0.0002″ tolerances on aerospace components

- High repeatability: Producing 10,000+ identical medical implants with <0.1% variation

- Increased efficiency and speed: Reducing complex part production from 8 hours to 45 minutes

- Flexibility in complex geometries: Machining 5-axis impellers with 0.2mm blade thickness

- Reduced material waste: Optimized tool paths saving 35% material on titanium aerospace parts

- Safer operations: Eliminating manual tool changes near rotating spindles

Industries that rely on CNC machining

- Aerospace: Turbine blades (Inconel), structural components (Ti-6Al-4V), landing gear

- Automotive: Engine blocks (A356 aluminum), transmission gears (8620 steel)

- Medical equipment: Titanium spinal implants, cobalt-chrome knee replacements

- Electronics: Copper heat sinks, aluminum smartphone frames

The Future of CNC Machining: Integrating Automation and Artificial Intelligence

Emerging technologies include:

- Machine learning algorithms predicting tool wear with 95% accuracy

- Adaptive control systems adjusting feeds/speeds in real-time

- Collaborative robots (cobots) loading/unloading parts autonomously

- Digital twin simulations reducing setup time by 40%

Conclusion

CNC machining continues to evolve as the foundation of precision manufacturing, with new advancements in automation and AI driving unprecedented levels of efficiency and capability. As tolerances tighten and materials advance, CNC technology remains essential for producing the complex components that power modern industry.