Precision CNC Turning Service

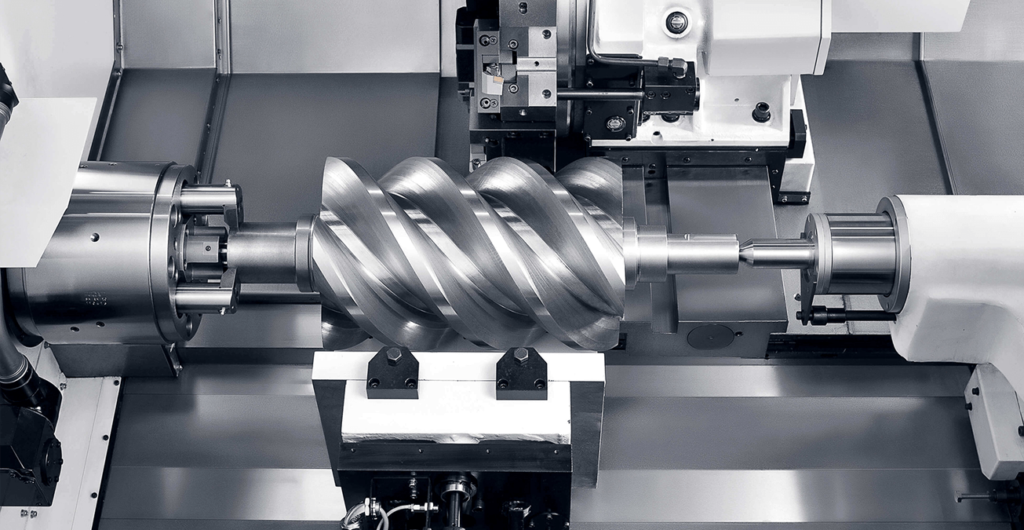

Precision CNC turning service allow for complex and precise machining of a wide range of materials to create high precision, high quality products.

Learn more1: ±0.005mm tight tolerance

2: Over 60 certified materials

3: 100% quality assurance.

Our CNC precision machining capabilities deliver high-tolerance (±0.005mm or better) components for industries demanding uncompromising accuracy, including aerospace, medical, automotive, and robotics.

Precision CNC turning service allow for complex and precise machining of a wide range of materials to create high precision, high quality products.

Learn moreWe offer precision CNC milling and 3-axis-4-axis milling services to help you quickly get custom CNC milled parts from simple to complex.

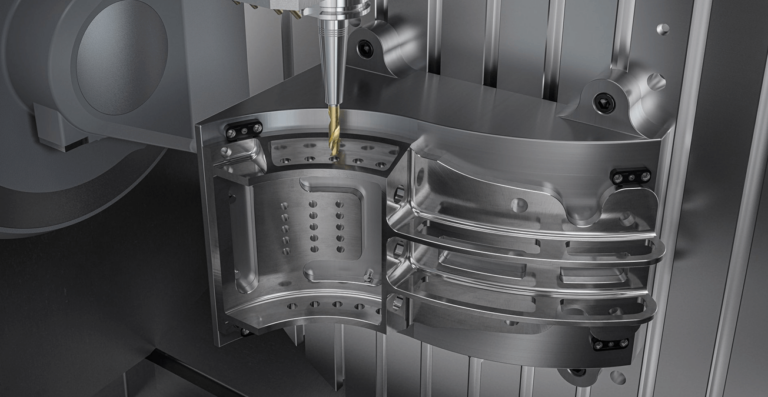

Learn moreOur 5-axis CNC service offers unrivaled precision and versatility to produce complex components to exacting CNC milling parts.

Learn more

The 5-axis CNC machining service stands out for its outstanding performance. It breaks through the limitations of traditional machining by linking three linear axes – X, Y and Z – with two rotary axes – A, B or C – to allow the tool to cut into the workpiece at any angle, making the machining of complex surfaces and precision structures a breeze.

Whether it is the streamlined surface of an aerospace engine blade or the personalized bionic structure of a medical implant, 5-axis CNC machining can achieve it with precision.

CNC milling service is a key force with its high precision and flexibility. Relying on advanced CNC equipments and professional technical team, our CNC milling service is able to accurately process all kinds of materials such as aluminum alloy, stainless steel, titanium alloy, engineering plastics and so on into complex precision parts according to your needs.

Whether it’s flat milling, contour milling, or 3D milling, the precise control of tool paths through computer programs, coupled with micron-level machining accuracy, allows us to efficiently complete tasks ranging from single-part customization to mass production.

30+ CNC lathes are available for OEM&ODM ordering with different MOQ requirements, supporting quick quote, sample trial and FAI, services covering 3/4/6/9-axis CNC milling and turning, slotting/drilling/reaming/boring/milling/tapping/inner/outer diameter turning of cylindrical features of complex parts in one go. Precision turned parts with diameters ranging from 2 to 450mm and lengths up to 1000mm can be processed.

Regardless of aluminum/copper/stainless steel/steel/titanium/plastic material, your CNC Machining Parts can be machined to the desired size to μm tolerance. A variety of surface finishes are available to meet your appearance needs, sandblasted/oxidized/plated/electrophoresis/painted/brushed with RoHS report.

High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. Can be anodized.

High tensile strength, corrosion and temperature resistant. Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished.

High machinability and weldability, high stiffness. Mild steels are low-carbon metal alloys offering good mechanical properties, machinability and weldability at low cost. Can be carburized to increased hardness.

Excellent thermal and electrical conductivity Copper offers excellent thermal and electrical conductivity, it's often used for busbars, wire connectors, and other electrical applications. Copper has a glossy reddish-orange appearance.

Excellent strength to weight ratio, used in aerospace, automotive and medical industries. Titanium is a metal with excellent strength-to-weight ratio, low thermal expansion and high corrosion resistance that is sterilizable and biocompatible.

Tool steel has high hardness and can maintain high hardness and red hardness at high temperatures, as well as high wear resistance and appropriate toughness. Tool steel is generally divided into carbon tool steel, alloy tool steel and high-speed tool steel.

Superalloys have excellent high-temperature strength, good oxidation resistance and hot corrosion resistance, good fatigue properties, fracture toughness and other comprehensive properties, and are mainly used in the aerospace and energy fields.

Brass has strong wear resistance, high strength and hardness, and strong resistance to chemical corrosion. Brass is often used to make wear-resistant parts such as valves and watch movements.

Alloy steel has special properties such as high strength, high toughness, wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, and magnetism.

Engineering plastics have excellent comprehensive properties, such as high rigidity, low creep, high mechanical strength, good heat resistance, and good electrical insulation. They can be used in harsh chemical and physical environments for a long time and can replace metals as engineering structural materials.