Important factors in the manufacture of metal parts: materials, processes and applications

Metal parts play a pivotal role in modern industry. From automotive manufacturing to aerospace, from medical devices to industrial equipment, the quality and performance of metal parts directly impacts every industry. Material selection, process type, and the intended use of the part are three critical factors in the manufacturing of metal parts. This article will delve into these three critical factors to reveal the mysteries of metal parts manufacturing .

1. Influential factors in the manufacture of metal parts

1- Mechanical properties

When selecting materials for metal parts, it is important to consider their mechanical properties, including hardness, tensile strength and ductility. Different application scenarios require different combinations of mechanical properties. For example, stainless steel is favored for its corrosion resistance and durability, especially in applications requiring high strength and good corrosion resistance, while aluminum is widely used in areas with stringent weight requirements such as automotive and aerospace due to its light weight.

2 – Corrosion resistance

Depending on the environment in which the part will be used, corrosion resistance is an important consideration. For parts used in harsh environments such as marine, medical or outdoor, it may be necessary to select a corrosion-resistant material such as stainless steel or anodized aluminum. These materials maintain their performance and appearance in harsh environments, extending the life of the part.

3 – Cost-effectiveness

Cost-effectiveness is also a key factor when selecting materials. Some materials, such as titanium and certain high-performance alloys, offer excellent performance but are more costly. Therefore, a balance between cost and performance needs to be found when selecting materials, especially for mass-produced parts.

4 – Processability

The machinability of a material affects manufacturing time and overall cost. Some metals, such as brass and aluminum, are relatively easy to machine, while harder materials, such as hardened steel or titanium, may require more time and specialized tooling for machining.

2、Metal parts manufacturing commonly used materials

1 – Steel

Steel is a ferrous alloy with a carbon content of about 1% that has high strength and great flexibility. It can be machined, stamped, roll-formed, welded, and processed in a variety of ways, making it one of the most commonly used materials in the manufacture of metal parts.

2 – Stainless steel

Stainless steel adds chromium content (10% or more by weight) to steel for corrosion resistance. Stainless steel parts are typically used in marine applications and chemical plants where corrosion resistance is important.

3 – Aluminum

Aluminum is a softer element and is often mixed with other elements such as copper, magnesium and zinc and heat-treated to improve its properties. Automobile and aircraft parts are often made of aluminum to reduce weight.

4 – Brass

Brass is an ideal choice when corrosion resistance is important. It is so versatile that many plumbing components such as valves are made from brass. Brass is also very strong and can be used to make everything from ship parts to coins.

5 – Copper

Copper has a fibrous structure and is difficult to process. However, because of its good electrical conductivity, it is an extremely important metal for power generation and is commonly used in electrical wiring and plumbing. Also, copper is often used as an element in many different metal alloys.

3, metal parts manufacturing process type

consideration

1 – Part geometry and complexity

For parts with complex shapes and rich details, it is necessary to select a process that enables high-precision machining. Processes such as CNC machining or precision casting may be more suitable for such parts. CNC machining allows tight tolerances and is ideal for parts that require precision machining.

2 – Production

The size of the production volume will also influence the choice of process. For small production runs or prototyping, processes such as CNC machining and 3D printing are more cost-effective and flexible. For high volume production, methods such as stamping, forging or die casting can help reduce unit costs.

3 – Tolerance and surface finish requirements

The required accuracy of the part determines the choice of machining process. CNC machining is well suited to achieve high tolerances, while processes such as forging may require secondary operations to meet tighter tolerances.

4 – Delivery time and flexibility

Different processes have different lead times and flexibility. For example, CNC machining has a shorter turnaround time and is well suited for rapid prototyping or small batch production.

Common Processes

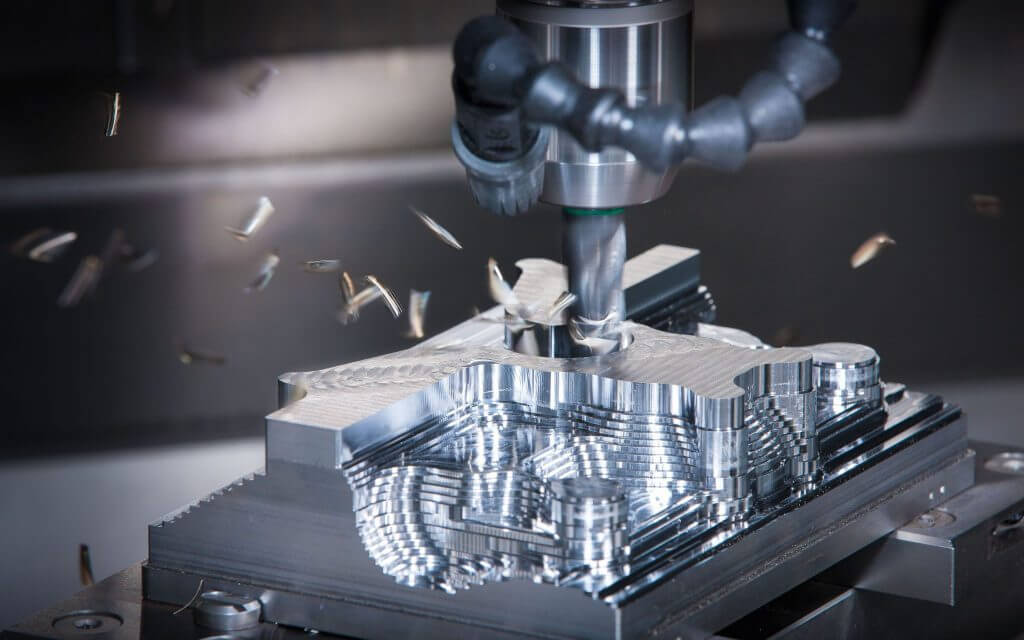

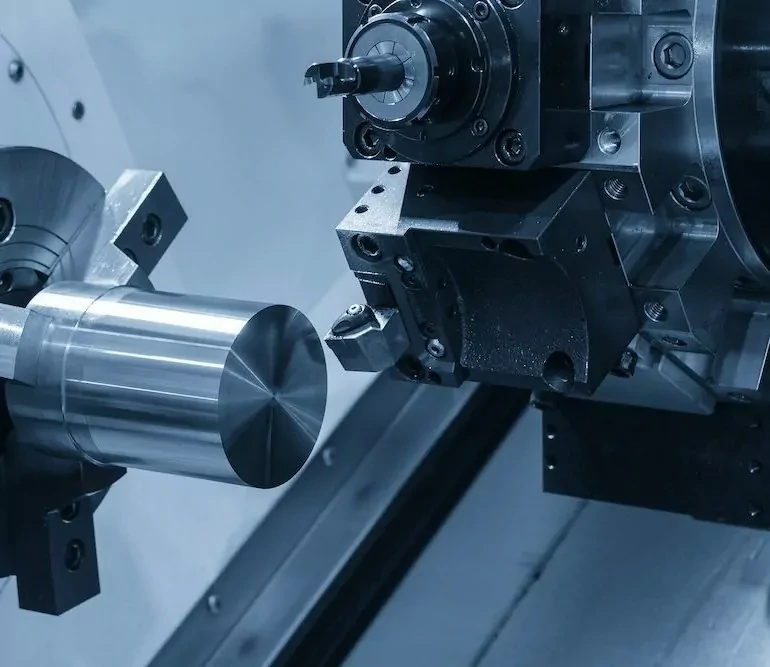

1 – CNC machining

Highly accurate and versatile for prototyping and production.

2 – Castings

Effective for a large number of complex shaped parts, but may require post-processing to ensure accuracy.

3 – Forging

Used to produce high strength, high stress parts, but less flexible for complex geometries.

4 – Sheet metal fabrication

Ideal for manufacturing parts such as housings and panels, commonly used in automotive and industrial applications.

4. Use of metal parts

1 – Automotive industry

Parts such as gears, axles and brackets in the automotive industry need to be durable, cost-effective and often produced in high volumes. Steel is popular because of its strength, but lightweight materials such as aluminum are also becoming increasingly popular.

2 – Aerospace

In aerospace, weight reduction is key, so materials such as titanium and aluminum are favored. Parts also need to be highly accurate and must withstand extreme conditions.

3 – Medical equipment

In the medical device field, where biocompatibility is critical, materials such as stainless steel and titanium are widely used for their sterilizable and corrosion-resistant properties.

5. Main considerations for metal parts

1 – Load and pressure

If parts are to be subjected to heavy loads or stress, they need to be made of strong and durable materials, and manufacturing processes must be chosen that ensure optimal strength. For example, forged steel is commonly used to make highly stressed automotive parts such as axles and crankshafts.

2 – Temperature and environmental conditions

Will the parts be exposed to extreme temperatures, moisture or chemicals? High-temperature environments may require heat-resistant alloys, while parts exposed to chemicals or moisture may require corrosion-resistant materials such as stainless steel or aluminum.

3 – Friction and wear

If the part will be subjected to friction, for example in moving machinery, then materials with wear-resistant properties, such as hardened steel or alloys with added coatings, should be considered.

4 – Accuracy Requirements

If the part is critical to the function of the assembly, such as in aerospace or medical devices, it must be manufactured to tight tolerances and surface finishes, requiring precise machining processes.

summarize

Material selection, the type of process and the intended use of the part are three key interrelated factors in the manufacture of metal parts. By carefully considering these factors, manufacturers can select the right material, utilize the best manufacturing process, and ensure that the metal part meets the needs of the specific application.