Precision CNC Turning Service

Trusted by the world's best companies

cnc precision turningType

4-Axis CNC Turning Service

CNC Milling And Turning Service

Swiss Turning Machining

CNC Tool Lathe Machining

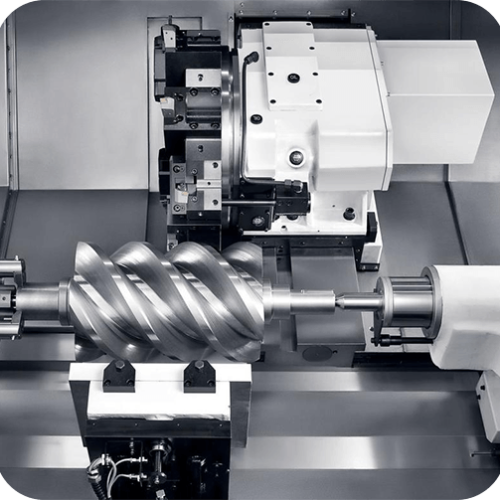

About CNC Turning Service

Precision CNC turning Service

Precision CNC turning service allow for complex, precision machining of a wide range of materials, enabling the manufacture of high-precision, high-quality products that are suitable for mass production and customized manufacturing.

SCZY LTD

50+

Available Materials

10+

Years Of CNC Experience

Maximum Size Of Precision CNC turning

Our cnc precision turned service has a maximum speed of 6000RPM, a maximum load capacity of 2T and a minimum compensation parameter of 0.0001mm.

| Part size limitations | Metric units | Metric unitsImperial units |

| Maximum part diameter | 825 mm | 32.48 in |

| Maximum part length | 1500 mm | 59 in |

| Maximum swing over the carriage | 430 mm | 16.93 in |

| Maximum spindle through-hole | 65 mm | 2.56 in |

CNC precision turning Service Tolerance

The maximum speed is 6000RPM, the maximum load-bearing capacity is 2T, and the minimum compensation parameter is 0.0001mm.

| Limits for nominal size | Plastics (ISO 2768- f) | Metals (ISO 2768- f) |

| 0.5mm* to 3mm | ±0.05mm | ±0.05mm |

| Over 3mm to 6mm | ±0.05mm | ±0.05mm |

| Over 6mm to 30mm | ±0.1mm | ±0.1mm |

| Over 30mm to 120mm | ±0.15mm | ±0.15mm |

| Over 120mm to 400mm | ±0.2mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.3mm | ±0.3mm |

| Over 1000mm to 2000mm | ±0.5mm | ±0.5mm |

| Over 2000mm to 4000mm | ±1mm |

Materials Available for CNC Turning Service

Our CNC turning service provide instant quotes for over 50 metal and plastic machining options for a variety of industry applications. Ideal for one-off prototypes and customized parts.

-

Aluminum $

Aluminum $High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. Can be anodized.

-

Stainless steel $$$

Stainless steel $$$High tensile strength, corrosion and temperature resistant. Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished.

-

Mild steel $

Mild steel $High machinability and weldability, high stiffness. Mild steels are low-carbon metal alloys offering good mechanical properties, machinability and weldability at low cost. Can be carburized to increased hardness.

-

Copper $$$

Copper $$$Excellent thermal and electrical conductivity Copper offers excellent thermal and electrical conductivity, it's often used for busbars, wire connectors, and other electrical applications. Copper has a glossy reddish-orange appearance.

-

Titanium $$$

Titanium $$$Excellent strength to weight ratio, used in aerospace, automotive and medical industries. Titanium is a metal with excellent strength-to-weight ratio, low thermal expansion and high corrosion resistance that is sterilizable and biocompatible.

-

Tool steel $$$

Tool steel $$$Tool steel has high hardness and can maintain high hardness and red hardness at high temperatures, as well as high wear resistance and appropriate toughness. Tool steel is generally divided into carbon tool steel, alloy tool steel and high-speed tool steel.

-

Superalloy $$$

Superalloy $$$Superalloys have excellent high-temperature strength, good oxidation resistance and hot corrosion resistance, good fatigue properties, fracture toughness and other comprehensive properties, and are mainly used in the aerospace and energy fields.

-

Brass $$$

Brass $$$Brass has strong wear resistance, high strength and hardness, and strong resistance to chemical corrosion. Brass is often used to make wear-resistant parts such as valves and watch movements.

-

Alloy steel $$

Alloy steel $$Alloy steel has special properties such as high strength, high toughness, wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, and magnetism.

-

Plastics $

Plastics $Engineering plastics have excellent comprehensive properties, such as high rigidity, low creep, high mechanical strength, good heat resistance, and good electrical insulation. They can be used in harsh chemical and physical environments for a long time and can replace metals as engineering structural materials.

CNC Turning Service Surface Finishes

Advantage

Supporting services

Standard (As-Machined)

Bead Blasting

Anodized (Type II Or Type III)

Powder coating

Polishing

Black-Oxide

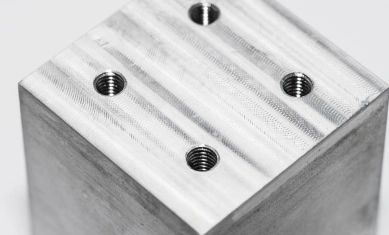

CNC Turned Parts Gallery

CNC Turning Service FAQ

What is CNC Turning Center?

What parts can be manufactured using CNC turning?

What is the difference between a CNC turning center and a CNC lathe?

What Are The Benefits Of CNC Turning?

What is the difference between rough turning and finish turning?

Why use CNC Turning?

High Precision: High precision of turning tool.

High efficiency: CNC turning machining process is simple, high efficiency, can quickly complete a variety of machining tasks.

Reliability: the turning tool is sturdy and durable, not easy to be damaged, and can be used for a long time.

Flexibility: CNC turning is suitable for a variety of materials and shapes of workpieces, and can realize a variety of processing purposes.