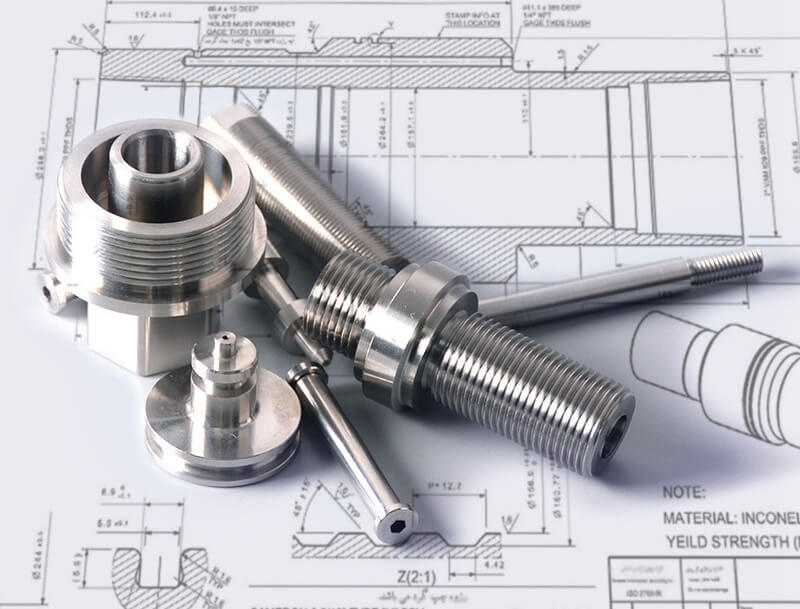

Comprehensive Guide to CNC Machining of Stainless Steel

1. What is Stainless Steel CNC Machining?

Stainless steel CNC machining is a precision manufacturing process that uses computer-controlled machine tools to shape corrosion-resistant steel alloys into complex components. This subtractive manufacturing method achieves tight tolerances (typically ±0.005″ or better) while maintaining the material’s exceptional properties.

Modern CNC centers can machine stainless steel parts with surface finishes down to 32 µin (0.8 µm) Ra, making them suitable for both functional and aesthetic applications in demanding environments.

1.1 Key Characteristics of Machinable Stainless Steel

- Chromium content ≥10.5% for corrosion resistance

- High strength-to-weight ratio (up to 1,000 MPa tensile strength)

- Excellent temperature resistance (-200°C to 800°C service range)

- Non-magnetic or magnetic variants available

- Biocompatible options for medical applications

2. Different Types of Stainless Steel for CNC Machining

Five main families of stainless steel used in precision machining:

2.1 Austenitic Stainless Steels (300 Series)

The most commonly machined group, offering:

- Excellent corrosion resistance

- Good formability and weldability

- Non-magnetic properties

- Contains nickel (8-11%) and chromium (18-20%)

2.2 Ferritic Stainless Steels (400 Series)

Magnetic alloys with:

- Lower nickel content (more economical)

- Good stress corrosion cracking resistance

- Higher thermal conductivity than austenitic

2.3 Martensitic Stainless Steels

Heat-treatable grades featuring:

- High hardness (up to 60 HRC)

- Excellent wear resistance

- Moderate corrosion resistance

2.4 Duplex Stainless Steels

Hybrid alloys combining:

- Strength of ferritic steels

- Corrosion resistance of austenitic

- Higher resistance to stress corrosion

2.5 Precipitation-Hardening Stainless Steels

Specialty alloys offering:

- Exceptional strength-to-weight ratio

- Good corrosion resistance

- Dimensional stability during heat treatment

3. Learn About the Different Grades of Stainless Steel

Machinability ratings of common stainless steel grades (1=best, 5=worst):

| Grade | Type | Machinability | Key Properties | Typical Applications |

|---|---|---|---|---|

| 303 | Austenitic | 1 | Added sulfur for improved machining | Fittings, shafts, fasteners |

| 304/L | Austenitic | 3 | Excellent corrosion resistance | Food processing, chemical |

| 316/L | Austenitic | 4 | Marine-grade corrosion resistance | Marine, medical, pharmaceutical |

| 410 | Martensitic | 2 | Heat treatable, magnetic | Cutlery, valves, pumps |

| 430 | Ferritic | 2 | Good formability, magnetic | Automotive trim, appliances |

| 17-4PH | Precipitation-hardening | 3 | High strength, corrosion resistant | Aerospace, nuclear, military |

4. Advantages of Stainless Steel in CNC Machining

Key benefits that make stainless steel ideal for precision components:

4.1 Superior Corrosion Resistance

- Withstands harsh chemicals and saltwater environments

- Ideal for marine, chemical, and medical applications

- Forms passive chromium oxide layer that self-repairs

4.2 Exceptional Strength and Durability

- High tensile strength (500-1000 MPa typical)

- Maintains properties at extreme temperatures

- Excellent fatigue resistance for dynamic applications

4.3 Aesthetic Versatility

- Multiple finish options: brushed, mirror, bead blasted

- Maintains appearance without plating/painting

- Hygienic surface for food and medical use

4.4 Long-Term Cost Effectiveness

- Lower lifecycle costs than plated carbon steel

- Reduced maintenance requirements

- 100% recyclable at end of service life

5. Overcoming Challenges in CNC Machining of Stainless Steel

Solutions for common stainless steel machining difficulties:

5.1 Work Hardening Issues

Problem: Stainless steels tend to harden during machining

Solutions:

- Maintain consistent feed rates (never pause during cut)

- Use sharp tools with positive rake angles

- Select appropriate cutting speeds (100-300 SFM for most grades)

5.2 Heat Generation and Tool Wear

Problem: High cutting temperatures reduce tool life

Solutions:

- Use carbide or ceramic cutting tools

- Apply high-pressure coolant (minimum 1000 psi)

- Optimize chip loads to carry heat away

5.3 Built-Up Edge Formation

Problem: Material adhesion to cutting edges

Solutions:

- Use tools with specialized coatings (TiAlN, AlCrN)

- Increase cutting speeds where possible

- Select tool geometries that promote chip evacuation

5.4 Dimensional Accuracy Challenges

Problem: Thermal expansion affects tolerances

Solutions:

- Allow for thermal growth in programming

- Use temperature-controlled environments

- Implement multi-stage machining with cooling periods

6. Essential Tools and Equipment for CNC Machining of Stainless Steel

Specialized tooling requirements for stainless steel:

6.1 Cutting Tools

- End Mills: 4-6 flute carbide with variable helix

- Drills: 135° split-point carbide drills

- Inserts: Grade C2 or C6 carbide with chipbreakers

- Specialty: Diamond-coated tools for finishing

6.2 Workholding Solutions

- High-pressure vacuum chucks

- Hydraulic expansion toolholders

- Custom soft jaws for delicate parts

- Magnetic chucks for ferritic grades

6.3 Coolant Systems

- High-pressure through-spindle coolant (1000+ psi)

- Synthetic coolants with extreme pressure additives

- Minimum quantity lubrication (MQL) systems

- Cryogenic cooling for difficult operations

6.4 Machine Requirements

- Rigid machine construction (≥20 HP spindle)

- High-torque spindles (50+ Nm at low RPM)

- Thermally stable bases (granite or polymer concrete)

- Advanced vibration damping systems

7. Stainless Steel CNC Machining in Key Industries

Critical applications across major sectors:

7.1 Aerospace and Defense

- Engine components (17-4PH, A286)

- Landing gear parts (Custom 450, 15-5PH)

- Missile and satellite components

- Typical tolerances: ±0.0005″ on critical features

7.2 Medical and Surgical

- Implantable devices (316LVM, BioDur 108)

- Surgical instruments (420, 440C)

- MRI-compatible equipment (304, 316 non-magnetic)

- Surface finishes: 8-16 µin Ra for implants

7.3 Energy and Oil/Gas

- Downhole tools (13Cr, Super Duplex)

- Valve bodies and stems (6MO, 254 SMO)

- Nuclear components (304L, 316LN)

- Pressure ratings: 10,000+ psi capability

7.4 Food Processing and Pharmaceutical

- Mixer blades and shafts (304, 316)

- Pump housings and valves

- Sanitary fittings and tubing

- Electropolished finishes for cleanability

7.5 Automotive and Transportation

- Fuel system components (409, 439)

- Exhaust systems (304, 321)

- Turbocharger parts (17-4PH, 15-5PH)

- High-volume production capabilities

8. Conclusion

Stainless steel CNC machining represents the pinnacle of precision manufacturing for demanding applications where corrosion resistance, strength, and reliability are paramount. While presenting unique machining challenges, modern CNC technology combined with proper tooling and techniques can produce stainless steel components with exceptional accuracy (holding ±0.0005″ tolerances), superior surface finishes (down to 8 µin Ra), and complex geometries unmatched by other manufacturing methods.

The versatility of stainless steel alloys – from free-machining 303 to ultra-corrosion-resistant super duplex grades – ensures solutions for virtually any industrial requirement. As CNC technology continues advancing with features like adaptive toolpaths, AI-driven process optimization, and hybrid manufacturing systems, the capabilities for stainless steel machining will only expand further.

For mission-critical components across aerospace, medical, energy, and other high-performance sectors, CNC machined stainless steel remains the material of choice when failure is not an option. By understanding the unique properties of different stainless grades and applying proper machining techniques, manufacturers can reliably produce components that withstand the most challenging environments while maintaining precision functionality for decades of service.