Titanium CNC Machining – Tips & Things to Consider

Titanium’s unique properties, such as its strength-to-weight ratio, corrosion resistance, and heat resilience, make it a preferred material in industries like aerospace, medical, and automotive manufacturing. However, these same properties also create unique challenges when it comes to machining. This article provides practical tips and strategies to help you master titanium machining and achieve better results.

Understanding Titanium and Its Machining Challenges

Titanium is renowned for its strength-to-weight ratio, being half as heavy as copper and possessing half the density of stainless steel. It excels in corrosion resistance and can withstand high temperatures without losing its mechanical properties. These characteristics make it ideal for harsh environments like marine and chemical processing setups. Additionally, titanium is non-magnetic and less electrically conductive than metals like copper, enhancing its applications in areas where magnetic and electrical interference must be minimized.

Despite its benefits, titanium presents several machining challenges. Its low thermal conductivity leads to heat retention in the cutting zone, increasing tool and workpiece temperatures. This, coupled with titanium’s chemical reactivity and gummy chips, can accelerate tool wear and lead to galling and heat buildup. Furthermore, titanium’s elasticity causes it to deflect under tool pressure, resulting in chatter and complicating the machining process.

Effective Machining Techniques for Titanium

To effectively machine titanium, a meticulous approach is necessary. Controlling heat, selecting the right tooling, implementing suitable coolant strategies, and maintaining machine stability are crucial. Due to titanium’s poor thermal conductivity and high chemical reactivity, optimizing machining parameters like speeds, feeds, and tool paths is essential. Slow cutting speeds and higher feed rates help manage heat concentration at the cutting zone, preventing tool wear and material damage.

Choosing the Right Tools for Titanium Machining

Machining titanium demands precision and resilience. Selecting the right tools is paramount to maintain productivity and minimize tool wear. Sharp carbide tools with specialized coatings like titanium aluminum nitride (TiAlN) or titanium carbonitride (TiCN) are recommended. High-speed steel tools enhanced with heat resistance properties are also useful, especially with smaller diameters to allow quicker cooling between cuts.

Optimizing Machining Parameters for Titanium

When machining titanium, using the correct parameters is critical. Titanium’s low thermal conductivity and high strength-to-weight ratio make it challenging to machine without precise control. Key parameters include cutting speed, feed per tooth, radial engagement, coolant pressure, and axial depth of cut. Optimizing these parameters helps manage heat generation and tool wear, ensuring high-quality machined parts.

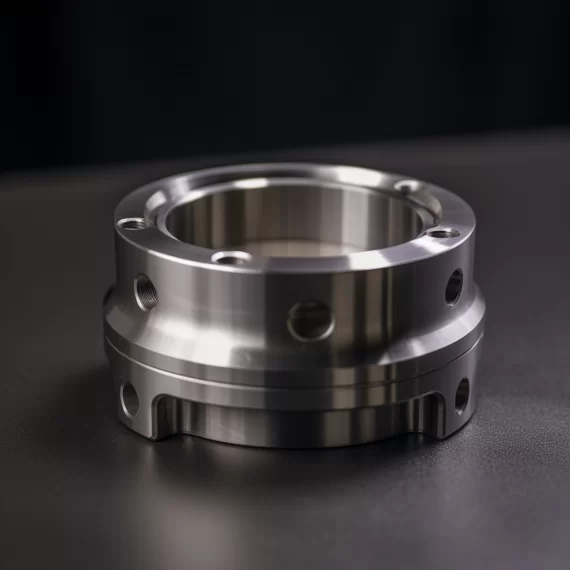

Applications of Machined Titanium Parts

Machined titanium parts are essential across various industries. They are used in aerospace, military, marine, medical, sports equipment, automotive, industrial, and power generation. These industries benefit from titanium’s ability to withstand extreme conditions while maintaining structural integrity and performance.

Common Challenges in Titanium Machining

Machining titanium can be complex due to its physical properties. Common challenges include heat buildup, galling, work hardening, vibration and chatter, short tool life, chip welding, and high costs. Addressing these challenges requires specialized tools, optimized cutting parameters, and effective coolant systems.

Cost Considerations in Titanium Machining

On average, machining titanium costs between $50 to $300 per hour. This depends on factors like part complexity, titanium alloy grade, and machining setup. The raw titanium material is expensive, often priced between $20 to $50 per pound. Longer cycle times and lower cutting speeds further increase operational costs.

Achieving Optimal Surface Finishes on Titanium

Achieving high-quality surface finishes on titanium requires precision. Strategies include using sharp tools, ensuring a stable setup, employing high-pressure coolant, optimizing cutting parameters, and performing finishing passes. Post-machining processes like polishing, grinding, deburring, and anodizing further enhance the final product.

Design Tips for Machining Titanium

Designing titanium parts requires careful consideration of the material’s properties. Tips include minimizing thin walls, ensuring proper chip evacuation, incorporating chamfers, designing for stable workholding, and optimizing tool access. These strategies help improve machining results.

Latest Advancements in Titanium Machining

Machining titanium has advanced significantly. Innovations include modern tool coatings like TiAlN and nano-composite coatings, advanced toolpaths such as dynamic milling and trochoidal cutting, cryogenic machining, ultrasonic machining, and high-torque machines. These advancements aim to extend tool life, improve surface quality, and reduce heat buildup.

Conclusion

Successfully machining titanium requires balancing the right tools, cutting strategies, and process control. Titanium’s strength and low thermal conductivity make it valuable but challenging to machine. By focusing on best practices, you can handle these challenges and achieve high-quality, precision machining.