What is CNC machining? Complete Basics for Getting Started

Wondering about CNC machining and its importance in manufacturing? You’re not alone. Computer numerical control (CNC) machining is a key element of modern manufacturing, using advanced technology to precisely cut, shape and manufacture parts.

This article details how CNC machines work and their role in the manufacture of everything from car parts to technological products. We will also learn about the many industries that rely on this technology and why it is so important.

CNC Machining Overview

CNC machining is controlled by a computer to produce high precision parts. In this process, the computer programme controls the movement of the cutting tool and the CNC programming controls the removal of material from the workpiece by the cutting tool to create the finished part.

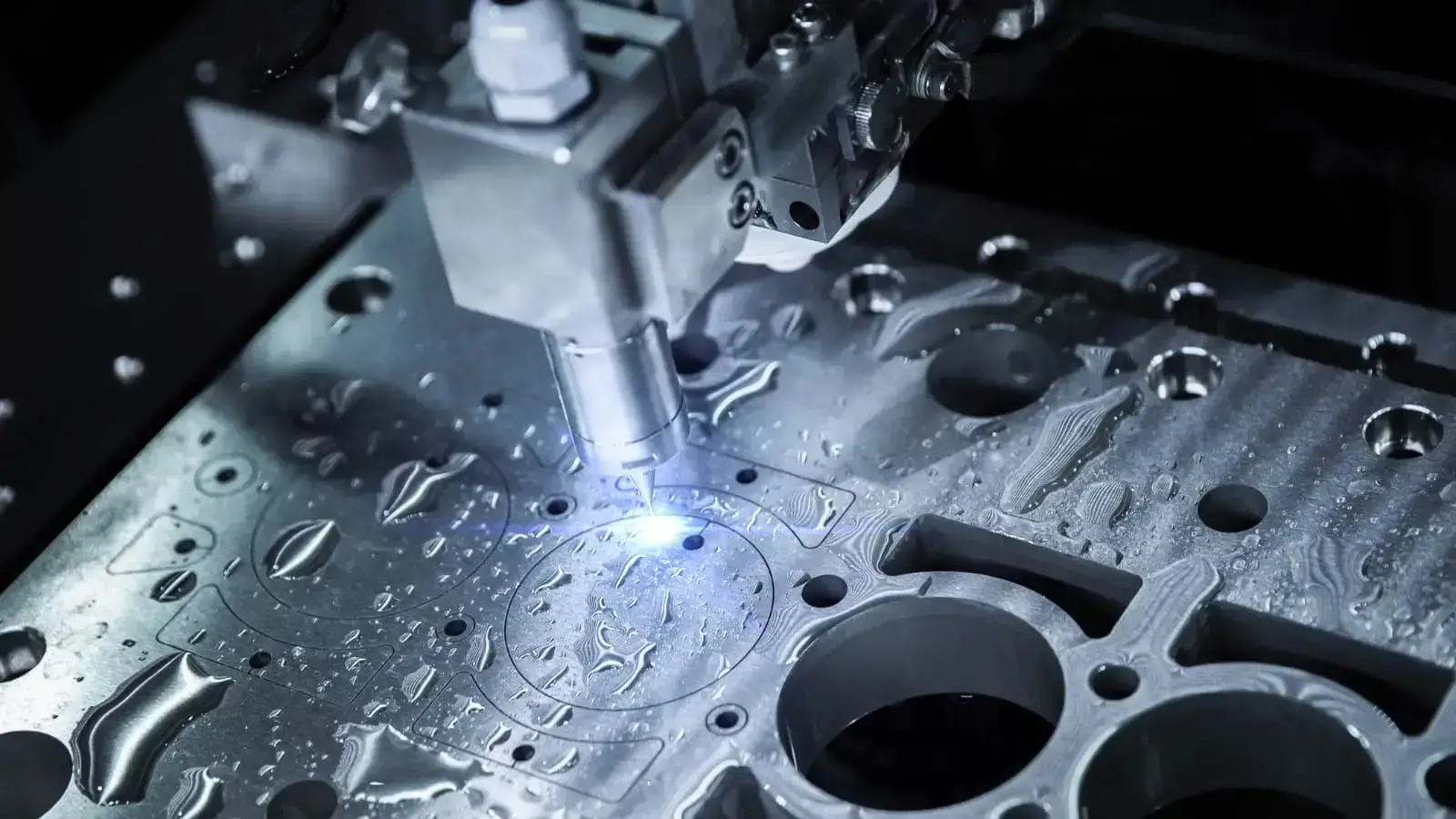

5-Axis CNC Machining Process

CNC technology can produce a range of parts, including those made from metals, plastics and other materials. The process can also produce parts with complex geometries and high precision, making it a popular choice for applications in a wide range of industries, including aerospace, automotive, medical devices and consumer goods.

It offers several advantages over traditional machining methods, including improved accuracy, consistency and speed, as well as the ability to produce complex geometries and intricate details. It also allows for the use of advanced cutting tools and techniques, such as multi-axis machining centres and high-speed machining, which can further improve the efficiency and quality of the process.

History of CNC machining

Its history dates back to the XNUMX era of the 1940s, when the first numerically controlled (NC) machines were developed. Over time, these machines have become more extensive and complex. This has enabled them to meet the requirements of various industries such as aerospace, automotive and defence. However, older NC machines still required manual input and had limited functionality.

The transformation of manufacturing began in the 1970s with the introduction of computers, which led to a breakthrough: the first CNC machine tools. These state-of-the-art, computer-controlled machines could process data with unprecedented speed and accuracy. This innovation dramatically streamlined the manufacturing process by allowing CNC operators to enter commands directly into the machine, which then automatically performed the necessary operations.

As technology has advanced over the years, this is only the beginning for CNC machines. The development of more advanced software and hardware as well as the introduction of new materials and tooling options means more possibilities for manufacturing units.

Today, CNC machinery is common in several industries and is capable of producing a wide range of high-precision products.

How does CNC machining work?

Modern CNCs are committed to minimising human intervention. This ensures consistent and continuous performance, which promotes smart manufacturing and delivers excellent results.

However, CNC manufacturing requires careful consideration from initial design to final manufacturing. The whole process is divided into three distinct steps:

1 - Design

The first critical step in CNC machining involves software applications such as CAD, CAM and CAE. Engineers and designers rely on these tools to design parts and products and then evaluate them for manufacturability. This evaluation, called design for manufacturing (DFM), is critical. It ensures that the design is optimised to maximise efficiency and minimise costs, while working within the constraints of existing technology.

In most cases, CAD tools on the market come with internal CAM tools, which help with pre-processing and programming.

Once the CAD design is complete, the designer converts it to a CNC-compatible file format, usually STEP or IGES.

2 - Pre-processing and programming

Programming a CNC machine mainly involves communicating with the machine using G-codes and M-codes. These codes are generated by CAM software packages and serve as a guide for cutting toolpaths in CNC operations.

Typically, if the design meets the DFM (Design for Manufacturing) criteria, the CNC machinist does not need to intervene in the pre-processing or operational phases. However, if the design does not meet these criteria, a degree of manual intervention may be required to ensure optimum performance.

Pre-processing is a standard step in CNC machining and its duration depends on the quality of the design. G-code or M-code programming usually takes only a few minutes. However, the success of CNC programming depends on the design adhering to DFM conventions. An accurate design will produce correct code and satisfactory results, while a flawed design will result in incorrect code and poor results.

3 - Machining

Accuracy in machine tool machining is critical, but replicating the exact dimensions of a CAD model is often challenging. This is why machinists often apply Standard ISO 2768 tolerances, which vary according to industry requirements. It is a widely accepted principle that tighter tolerances lead to increased manufacturing costs.

Common CNC operations in the industry

CNC machining is a versatile process whose operations vary according to specific requirements. Simple designs can be realised with a single operation, such as milling. However, more complex designs usually require a greater variety of operations.

Below are some of the key CNC machining equipment widely used in the industry.

CNC Milling Machine

CNC Milling is a highly accurate and versatile machining process used to remove material from a solid block to form a specific shape or design. It involves the use of a CNC system to manoeuvre a multi-point cutting tool (usually a milling cutter) with extreme precision. In this process, the workpiece is securely mounted on a table and the milling cutter rotates at high speed to systematically cut the material. This method is particularly effective for generating flat surfaces, but its capabilities extend far beyond simple shapes.

One of the main features of CNC milling machines is the ability to create complex geometries efficiently by intermittent cutting through multiple machining steps. This technology has been developed to include 3, 4 and 5-axis milling machines:

- 3-axis milling: Movement along the X, Y and Z axes allows basic operations such as drilling and planning. This method is ideal for simple projects requiring simple shapes and is popular for its simplicity. However, it is limited in the creation of complex geometries and is therefore best suited to less complex designs.

- 4-Axis Milling: Adding a rotary axis allows for more complex operations than 3-axis milling. This method is ideal for angle cutting and more complex shapes, extending the capabilities of CNC machining. It is particularly useful for parts that require extra precision that 3-axis milling cannot provide.

- 5-Axis Milling: The pinnacle of CNC milling, this method of machining moves along five axes simultaneously, allowing for extreme precision and complexity. It is invaluable in the high-precision industry for creating complex shapes with tight tolerances. The method streamlines production by reducing the need for multiple setups, ensuring efficiency and accuracy.

CNC turning

CNC turning is a highly efficient machining process used primarily for the shaping of cylindrical workpieces, but can also handle square or hexagonal raw materials. At the heart of CNC turning is the use of a computer-controlled lathe that uses a variety of cutting tools to rotate the workpiece. These tools trim and shape the material into the desired cylindrical shape.

The uniqueness of the lathe lies in its versatility and precision, determined by the different spindle and speed capabilities. The process can be performed on both vertical and horizontal settings, each of which is suitable for specific types of workpieces and machining requirements.

这是测试文本,单击 “编辑” 按钮更改此文本。

There are two main types of machines:

- CNC Lathe: It specialises in precision turning and is ideally suited to machining high precision cylindrical parts. It operates by rotating the workpiece on a stationary tool, and is ideal for simple to moderately complex shapes, often used in the automotive and aerospace industries.

- CNC Turning Centre: It combines turning with additional functions such as milling and drilling. This multitasking capability allows complex parts to be produced in a single setup, resulting in increased efficiency and accuracy. It is vital for industries that require complex, multifaceted components, such as advanced manufacturing.

CNC Drilling

Drilling is an important manufacturing process that produces threaded holes of different sizes in a workpiece. The process is fully automated thanks to a computer that precisely controls the movement and speed of the drill.

CNC drilling is common in many industries, including printed circuit boards, metal parts and plastics. The process offers several advantages over traditional manual drilling, including greater accuracy, repeatability and efficiency.

CNC Routing

The rough operation of a CNC router is the same as a milling machine. Routers typically work with softer materials such as wood, while milling is typically used for harder metals. Like any CNC operation, routers offer excellent consistency, efficiency and accuracy.

During milling, the workpiece remains completely stationary while the spindle moves in different directions. Since milling is applied to softer materials, the overall speed of the spindle may be quite low. There are a variety of CNC milling machines available, including table milling machines, gantry milling machines and mobile gantry milling machines. The choice of machine and cutting tool will depend on the specific requirements of the workpiece and the desired end product.

electrical discharge process

An Electrical Discharge Machining (EDM) is a manufacturing process that uses electrical spark discharge to erode materials and produce complex shapes and geometries.

The process works by creating a spark between the electrode and the workpiece. The machinist immerses the workpiece in a dielectric fluid that isolates the electrical energy and allows precise control of the spark. The spark discharge vaporises the workpiece and removes access material to obtain the desired shape.

There are two main types of EDM: EDM moulding machines and EDM wire cutting machines. Sinker EDMs use expendable electrodes to generate sparks. In contrast, EDM wire cutting uses a thin wire that moves back and forth to create a spark.

CNC plasma cutting

CNC Plasma Cutting A dynamic manufacturing process used in a wide range of large industrial environments, CNC Plasma Cutting is renowned for its ability to cut conductive materials such as steel, stainless steel, aluminium, brass and copper with high speed and precision. The method involves a plasma torch, which generates a powerful plasma arc between the electrode and the workpiece, effectively melting and evaporating the material at the point of contact. A key component of the process is a high-pressure gas stream, such as air or nitrogen, which expels the molten material from the cutting area, resulting in clean, precise edges with minimal distortion or discolouration.

The technology stands out for its versatility in seamlessly cutting both thin and thick materials, thus broadening its industrial applications. In addition, plasma cutting is cost-effective, with lower operating costs compared to other methods. Its combination of speed, precision and affordability makes it an important tool for modern manufacturing, especially in industries where efficiency and accuracy are critical.

CNC Laser Cutting

CNC laser cutting is an essential component of industrial manufacturing, acclaimed for its precision and speed. It uses advanced lasers, including CO2, Nd and Nd:YAG types, which effectively vaporise the material to ensure a clean and precise cut. The technology is versatile and can handle a wide range of materials, making it widely used in a variety of industries.

The accuracy of the technology is not limited to a single operation; it offers excellent repeatability, which is essential for mass production. This consistent accuracy is particularly beneficial for industries such as aerospace and automotive, where precision is critical. CNC laser cutting is also known for its efficiency, minimising material waste and superior accuracy. In addition, the process simplifies workpiece clamping and reduces workpiece contamination, which increases overall productivity. With its ability to make fine cuts and maintain tight tolerances, it has become an indispensable tool in contemporary manufacturing.

CNC Machine Types: Introduction

The functionality of CNC machines varies greatly, influenced by their complexity and cost. Some machines are versatile and can perform a range of operations, while others are specialised for specific tasks. The following are the most common types of CNC machines in the industry:

3-, 4- and 5-axis machines:

Milling machines: They perform complex material removal using a variety of tools, including lathes and water jets. Running across multiple axes (horizontally, vertically and at angles), these machines handle fine milling of wood, metal and plastics, increasing efficiency by minimising material repositioning.

Lathe:

The turning process involves fixing material to a rotating mechanism, usually a lathe. As the material rotates, the CNC tool removes a small amount of material to achieve the desired shape, effectively producing cylindrical and tapered parts in a precise and consistent manner.

CNC Milling Machine:

Designed for precision, the CNC router cuts and shapes materials such as wood, plastic and metal, providing intricate 3D designs for industries that require detailed patterning and high precision.

Surface grinding machine:

CNC grinding machines use grinding wheels to achieve excellent surface finishes. This material reduction process achieves excellent precision and reduces the tolerance of surface defects to 0.1 mm, making it the preferred choice for high-quality surface finishes.

EDM machine tools:

Advanced cutting methods include EDM and WEDM. EDM uses electrodes for controlled thermal erosion in a dielectric fluid, while WEDM uses fine wire electrodes for complex, fine cuts.

Plasma cutting machine:

These machines use high-temperature plasma to efficiently cut conductive materials such as steel and aluminium, providing fast and accurate results for industrial metalworking projects.

Laser cutting machine:

The focused laser beam allows for clean, intricate cuts and engraving on metals, plastics and glass, making it ideal for aerospace, jewellery and electronics applications.

CNC machining parameters

CNC machining is known for its precision and versatility, guided by parameters set during G-code generation. At SCZY LTD, our CNC milling systems can handle parts up to 4000 x 1500 x 600 mm (157‘ x 59’ x 24″) in size, providing a much larger build area than a 3D printer. For CNC turning, we are equipped to machine parts up to 200 mm (7.9 in) in diameter, accommodating a wide range of component sizes. Our CNC machines are capable of outstanding accuracy, with tolerances as low as ±0.001 inches (±0.025 mm), which is less than half the diameter of an average human hair. Fast and Straightforward We can meet your needs with typical lead times of 5 business days and 1 day for simple parts. We are committed to precision and efficiency.

Common CNC Materials and Finishes

Below is a brief list of common CNC materials:

- stainless steels

- aluminium

- titanium

- copper

- brass

- Other alloys

- plastics

Below is a list of common CNC surface finishes:

- sandblast

- powder coating

- anodic oxidation

- lacquer

- burnish

- hot treatment

- Black oxides

Common applications for CNC machined parts

The machining process is known for the precision with which it creates CNC parts, and is used in a variety of capacities in numerous fields. Industries that benefit most from CNC machining capabilities include:

| Industries | appliance |

| aerospace | Core engine components |

| Automotive | Engine components, transmission components, suspension components. |

| Medical devices | Implants, prostheses and surgical instruments. |

| consumer product | Electronics, toys and common household items. |

| Machinery and tools | Pumps, valves and gears. |

Advantages and disadvantages of CNC machining

| vantage | drawbacks |

| Cutting tools can be precisely controlled to produce parts with tight tolerances and excellent repeatability. | CNC machines are quite expensive. Moreover, there are many types of them and most of the operations are not interchangeable. |

| The machine can run at high speeds, allowing parts to be produced faster. | The need for trained operators: Unlike conventional machines, CNC operators require extensive training before they can start working. This means they are in greater demand and have higher salary requirements. |

| It ensures consistent quality, which is useful for consumer products or high-volume production. | While efficient, some CNC operations may waste more material than manual processes. However, the precision, repeatability and efficiency they offer may offset this disadvantage in many cases. |

| Flexibility to create a wide range of parts, from simple to complex designs, through effective programming and correct machining methods. | |

| It is cost-effective for mass production, utilising economies of scale to reduce unit costs and meet the industry's need for efficiency and affordability. | |

| As most processes are automated, they are optimised to perform consistently without any intervention. This reduces overall maintenance requirements. |

Conclusion

As the core technology of manufacturing, CNC machining is widely used in aerospace, automotive, machinery and equipment industries due to its excellent machining accuracy, productivity and design flexibility. For manufacturing enterprises, mastering the basics of CNC machining, and the rational use of its advantages, to improve product quality, shorten the delivery cycle are of great significance.

For further guidance, contact our CNC experts who can help you make the perfect choice.