What is CNC Milling Machine?

Introduction

CNC milling machines have revolutionized the manufacturing industry, playing a pivotal role in the production of countless components that we encounter in our daily lives. From the intricate parts inside our smartphones to the robust components of aircraft engines, these machines are the backbone of modern precision manufacturing. So, let’s embark on a detailed exploration of what exactly a CNC milling machine is and how it functions.

Defining the CNC Milling Machine

First and foremost, CNC stands for Computer Numerical Control. A CNC milling machine, therefore, is a type of machine tool that uses computerized controls to operate. Unlike traditional milling machines, where an operator manually controls the movement of the cutting tool, a CNC milling machine relies on pre-programmed software instructions. These instructions guide the machine’s actions, enabling it to perform complex machining operations with high precision and repeatability. In essence, a CNC milling machine is like a highly skilled automated craftsman, capable of transforming raw materials into precisely engineered parts.

How Does a CNC Milling Machine Work?

Subsequently, to understand the operation of a CNC milling machine, let’s break down its key components and how they interact. At the heart of the machine is the controller, which is the brain that reads and interprets the G-code program. G-code is a standardized programming language for CNC machines, and it contains commands that specify details such as the tool path, cutting speed, feed rate, and depth of cut.

The spindle is another crucial component. It holds the cutting tool and rotates it at high speeds. Depending on the type of machining operation and the material being cut, the spindle speed can range from a few hundred to tens of thousands of revolutions per minute (RPM). For example, when machining soft materials like aluminum, a higher spindle speed can be used to increase the cutting efficiency. Alongside the spindle, the worktable is where the workpiece is securely held in place. The worktable can move along multiple axes, typically the X, Y, and Z axes, and sometimes additional axes like A, B, or C in more advanced machines. This multi-axis movement allows the machine to create complex three-dimensional shapes.

Types of CNC Milling Machines

Next, there are several types of CNC milling machines, each designed for specific applications. The most common ones are vertical milling machines, horizontal milling machines, and 5-axis milling machines.

Vertical Milling Machines

Vertical milling machines feature a spindle that is oriented vertically. They are highly versatile and are widely used for machining flat surfaces, slots, and holes. One of the advantages of vertical milling machines is that the operator can easily access the workpiece from the side, which makes it convenient for setting up and inspecting parts. These machines are commonly found in small to medium-sized manufacturing shops and are suitable for producing a variety of components, from simple brackets to complex mold cavities.

Horizontal Milling Machines

On the other hand, horizontal milling machines have a horizontally oriented spindle. They are better suited for machining large workpieces and performing operations that require a large cutting force, such as face milling and boring. The horizontal orientation allows for longer tool reach and can handle heavier cuts, making them a popular choice in industries that produce large mechanical parts, like automotive engine blocks or large industrial gears.

5-Axis Milling Machines

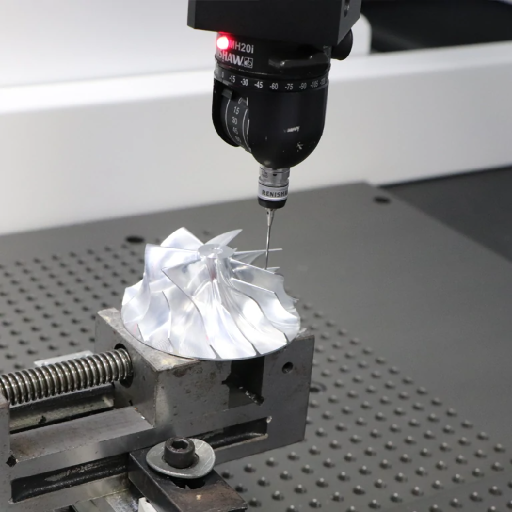

Then, 5-axis milling machines represent the pinnacle of CNC milling technology. In addition to the traditional X, Y, and Z axes, they have two additional rotary axes, usually A and B or A and C. This extra degree of freedom enables the cutting tool to approach the workpiece from any angle, allowing for the machining of extremely complex shapes that would be impossible or very difficult to produce with 3-axis machines. 5-axis milling machines are widely used in high-end industries such as aerospace, medical device manufacturing, and high-precision mold making.

Materials Suitable for CNC Milling Machines

Subsequently, CNC milling machines can work with a wide range of materials. Metals are among the most commonly machined materials. Aluminum, for instance, is popular due to its lightweight nature and good machinability. It is widely used in industries such as aerospace, automotive, and consumer electronics. Steel, ranging from mild steel to high-strength alloy steels, is also frequently machined. It is used in construction, machinery, and tool manufacturing. Titanium, known for its high strength-to-weight ratio and corrosion resistance, is commonly used in aerospace and medical implants. Copper and brass, with their excellent electrical conductivity and good machining characteristics, are suitable for electrical components and decorative parts.

Besides metals, many non-metallic materials can also be machined using CNC milling machines. Plastics like ABS, PVC, and nylon are often used in prototyping, consumer products, and industrial applications. Composites, such as carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), are gaining popularity in aerospace and high-performance automotive industries due to their high strength and low weight. Additionally, materials like wood and graphite can be machined for specialized applications such as woodworking and electrical discharge machining (EDM) electrode production.

Applications of CNC Milling Machines

Now, the applications of CNC milling machines span across numerous industries. In the aerospace industry, these machines are used to produce critical components such as turbine blades, engine casings, and structural parts. The high precision and repeatability of CNC milling machines ensure that these parts meet the strict tolerances and performance requirements of aircraft. For example, turbine blades are often made from high-temperature alloys and require complex 5-axis machining to achieve the aerodynamic shapes needed for efficient engine operation.

In the automotive manufacturing industry, CNC milling machines play a vital role in producing engine components, transmission parts, and custom prototypes. They allow for the rapid production of parts with tight tolerances, which is essential for the performance and reliability of modern vehicles. Moreover, they enable the production of complex shapes for lightweighting purposes, helping to improve fuel efficiency.

The medical device production industry also heavily relies on CNC milling machines. Medical devices, such as orthopedic implants, surgical instruments, and dental prosthetics, require extremely high precision and surface finish. CNC milling machines are used to machine these parts from biocompatible materials like titanium and stainless steel. The ability to produce customized parts based on patient-specific data, thanks to CNC technology, has revolutionized the field of personalized medicine.

Furthermore, in the consumer electronics industry, CNC milling machines are used to produce components for smartphones, laptops, and tablets. Aluminum casings, for example, are milled to achieve sleek designs and precise fits for internal components. CNC milling also enables the production of small, intricate parts like connectors and heat sinks with high accuracy.

Advantages of CNC Milling Machines

Another important aspect is the advantages that CNC milling machines offer. One of the key benefits is high precision. These machines can achieve tolerances as tight as ±0.001 mm, ensuring consistent quality in part production. This level of precision is crucial in industries where even the slightest deviation can lead to significant performance issues.

Automation is also a major advantage. Once programmed, CNC milling machines can run continuously with minimal human intervention. This increases productivity and reduces labor costs. Moreover, they can operate 24/7, allowing for faster production turnaround times. The ability to produce complex shapes is yet another significant advantage. CNC milling machines can create parts with intricate geometries that would be difficult or impossible to produce using traditional machining methods. Additionally, they offer excellent repeatability. Identical parts can be produced over and over again with the same high level of accuracy, making them ideal for mass production.

Finally, CNC milling machines provide flexibility. They can easily adapt to different materials, part designs, and production requirements by simply changing the CNC program. This makes them suitable for both small batch production and large-scale manufacturing runs.

Limitations of CNC Milling Machines

However, it’s important to note that CNC milling machines also have some limitations. The initial setup costs are relatively high. Purchasing a CNC milling machine, along with the necessary software, training, and tooling, represents a significant investment. Programming complexity is another challenge. Creating accurate G-code programs for complex parts requires skilled programmers and can be time-consuming. Moreover, CNC milling is a subtractive manufacturing process, which means it removes material from a workpiece. This can result in significant material waste, especially for parts with complex internal structures. Finally, the size of the parts that can be machined is limited by the size of the machine’s worktable and the reach of the cutting tool.

Conclusion

In conclusion, a CNC milling machine is a remarkable piece of equipment that has transformed the manufacturing landscape. With its ability to produce high-precision parts, automate processes, and handle complex shapes, it has become an indispensable tool in numerous industries. While it has its limitations, ongoing technological advancements are continuously expanding its capabilities. Whether you are involved in aerospace, automotive, medical, or consumer electronics manufacturing, understanding what a CNC milling machine is and how it works is essential for staying competitive in today’s global market.